Marc at Frankenstein Motorworks used this intake as a key part of his 405whp NA build. I highly doubt I will ever build mine to that level, but I am very interested to see what it does on a more mild build.

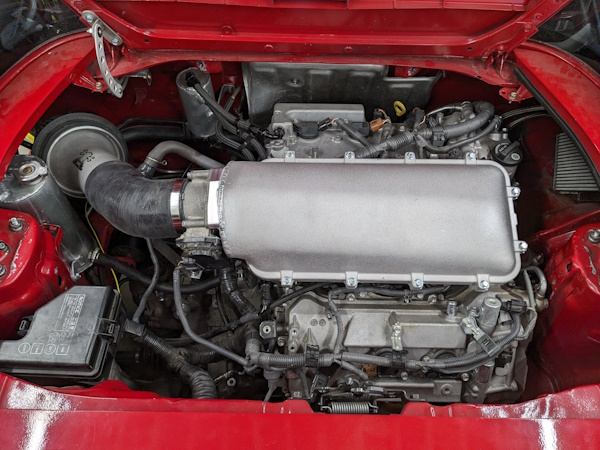

Before we jump into installation, lets just take a moment... this thing is pretty.

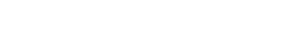

However, when you install it in the engine bay with the Holley plenum, it's a bit... big! Might be hard to fit the rest of the intake in the engine bay (if you watch Marc's test video, he didn't for the initial test).

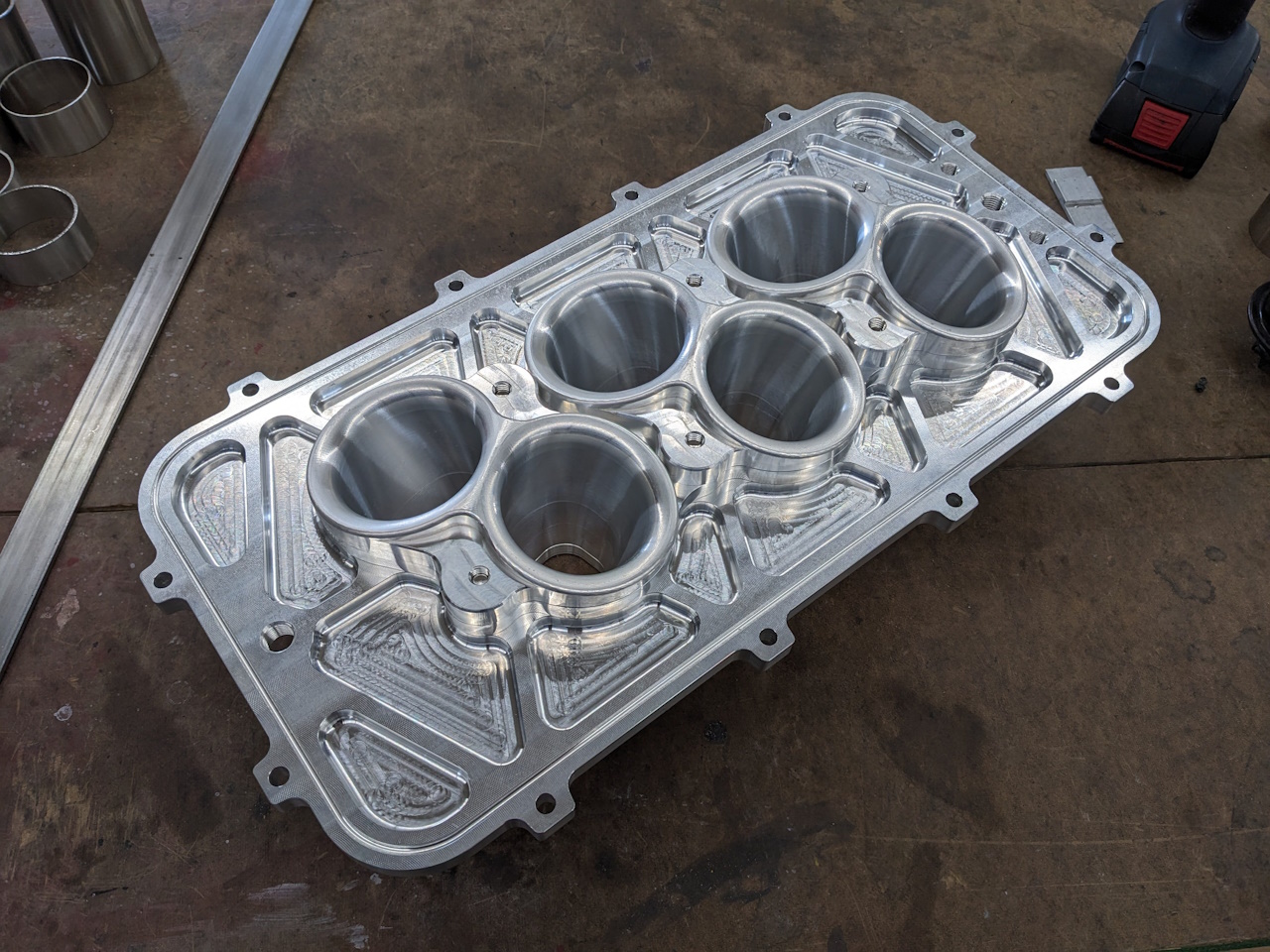

But what if we shortened the plenum a bit? That inlet neck on the Holley plenum is a bit absurd if you ask me.

Yes, if we cut the inlet off of the plenum, it should fit a lot better. And this way I can make a custom flange that fits the 76mm Toyota throttle (from the 3UR-FE V8) without an additional adapter.

So we do a little CAD work, and 3D print a prototype flange. Install with a bit of painters tape to check the fit. This allows the MAF pipe to easily fit in the engine bay, and allows my intake elbow for the 76mm throttle body to be used.

And then we wait on the machine shop for the real parts. In the mean time, I modified the engine lid to clear the plenum. With the optional 10mm spacer, this is the modification required to clear with the Turbo lid. It clears, just barely. It's snug, but as long as the engine motion is rocking forward and back (which it should be) I think it will be OK. I do not have an NA engine lid so I cannot comment on clearance with that.

Throttle body flanges finally came in from the machine shop! A little welding and it's ready to install. This modified plenum is available in my store.

I assembled the intake, plenum, and throttle body as one unit before installation. Installation of that assembly to the motor is a bit tricky. The bolts are NOT easy to reach! I found a miniature ratchet as shown below to be key. You also may wish to replace the stock bolts with some slightly shorter M6 socket head cap screws, just to reduce the number of turns required to tighten them. I switched mine out for some that are 20mm long. It also might help to polish the threads with a wire wheel to reduce friction. Also, the stock studs on the lower manifold are a little too long for the bottom plate on the FMW intake, so it's best to add an M6 washer under the nuts on either end of the intake.

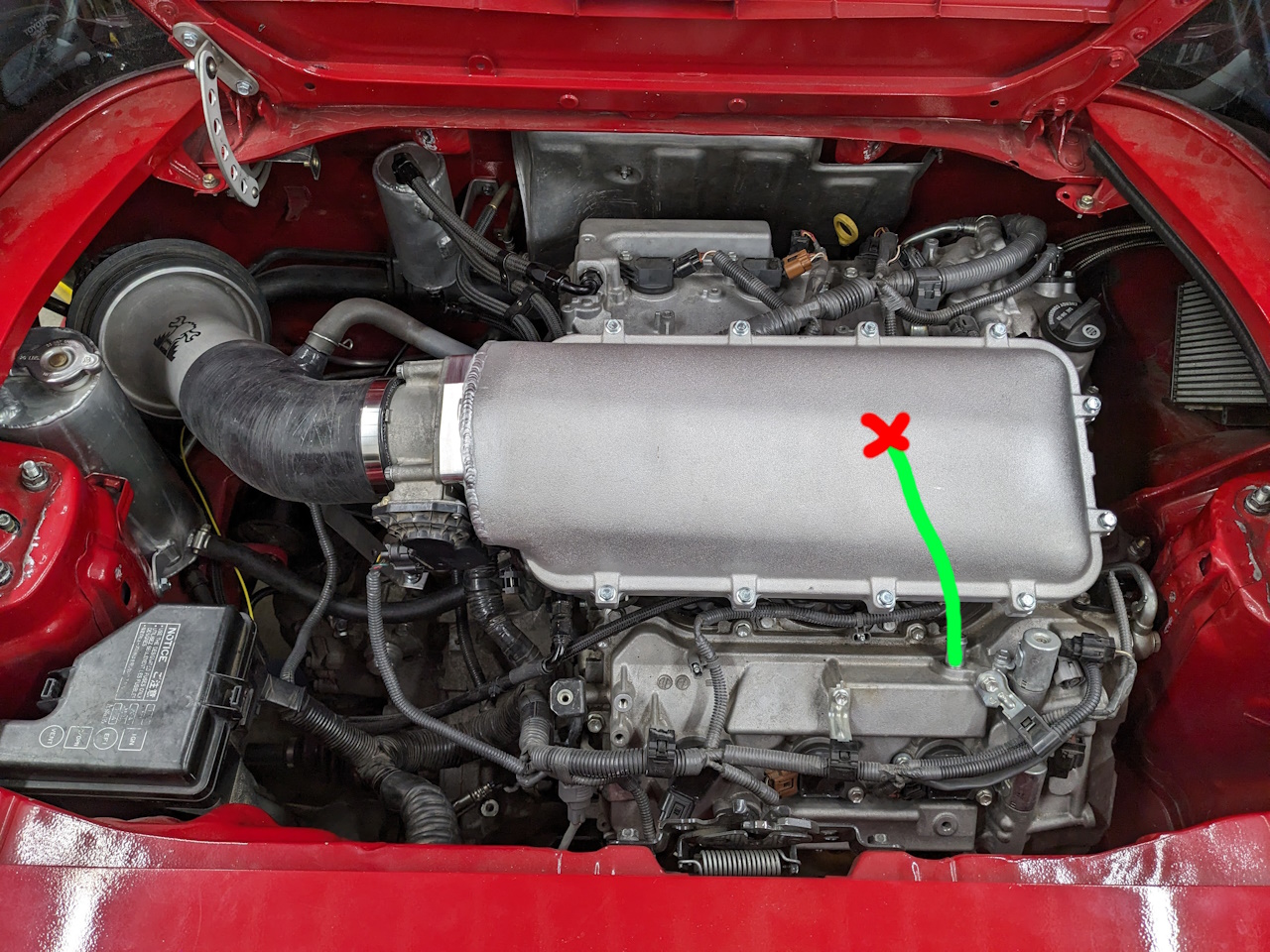

I connected both the PCV line from my catch can and the brake booster to ports under the throttle body. The FMW intake has 3 ports on one end, and one on the other. The way mine was initially assembled, the 3 ports were at the RH end of the intake, by the strut tower. If you want to reverse it like I did, make sure to remove, rotate, and reinstall the bottom plate. Otherwise it will be slightly mis-aligned where it meets the lower runners (the low runners / bottom plate are not symmetric). The stock PCV inlet hose must be extended to reach from the intake elbow to the rear bank valve cover. I used a piece of oil rated hose from McMaster Carr to extend it as shown below. New hose in green, splice point at the red X under the manifold. There is just room between the runners for the hose. This worked nicely with the stock hose (at least the one from my Rav4 motor) without needing to trim the stock hose. Also this should be obvious, but the old water neck mounted coolant filler will not clear the intake. But it works great with my expansion tank.

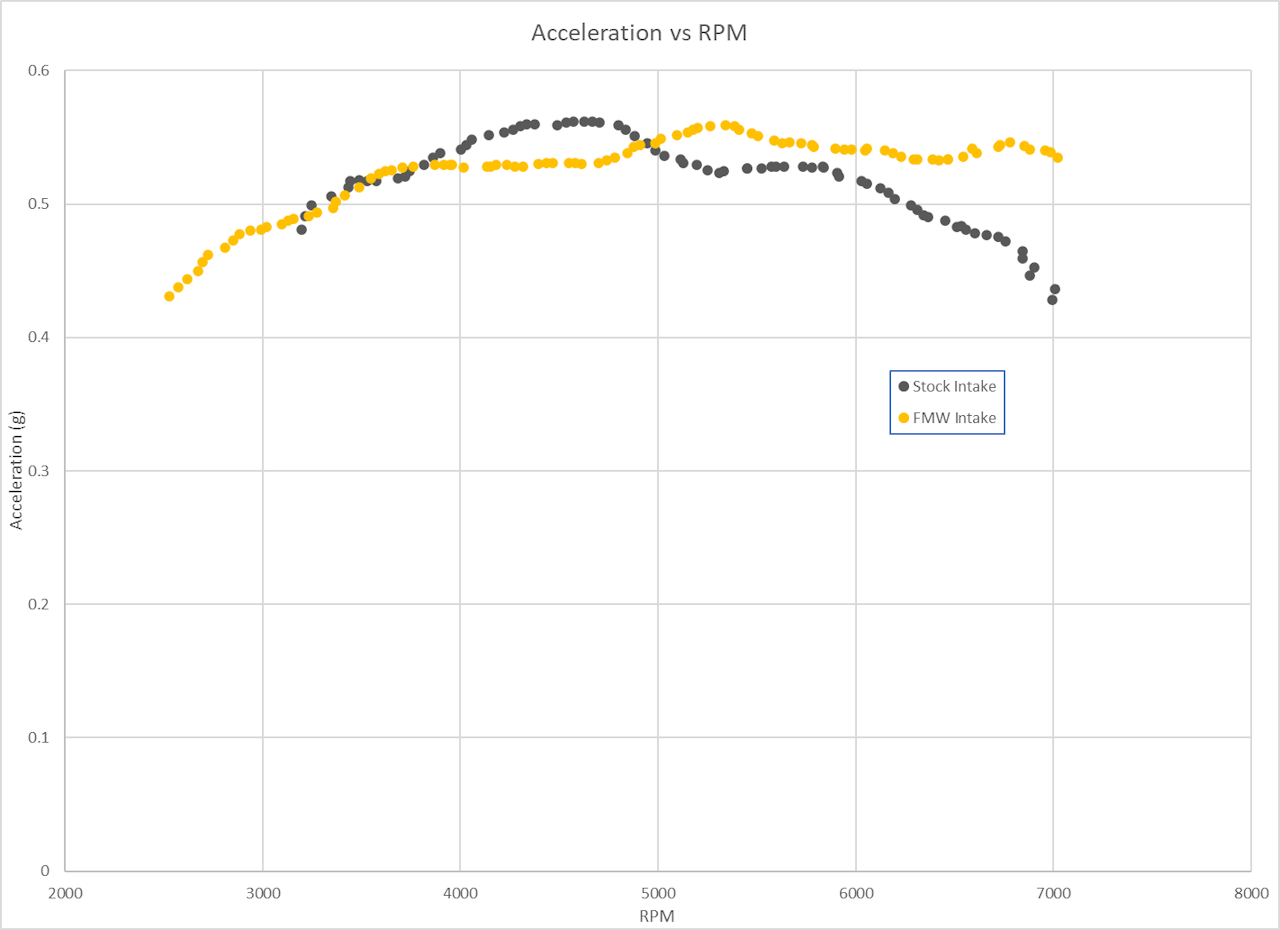

I don't have a dyno with the new intake yet. But what I do have is acceleration data taken with my Race Capture Pro data logger on a couple of street pulls, which is the next best thing (in theory, acceleration should mimic the shape of the torque curve). These are two 2nd gear pulls, done on the same day on the exact same stretch of road.

The very bottom end (below 3700 rpm) appears to be identical. There is some loss between about 3700 and 5k RPM. Above 5k, where the torque curve with the stock manifold starts to fall of, the FMW intake just keeps pulling. This was with stock cams, a Frankenstein Motorworks tuned ECU, and my X-pipe exhaust system. It really needs more RPM to truly shine I think, but the results are so far quite promising. My next step will likely be to install some valve springs and rev it a bit higher to see just how far it wants to go with stock cams.