In the quest for weight reduction, the power steering system is often targeted. I tried my car without power steering once, and absolutely hated it! And yet, here I am looking for places to save weight...

Electric power steering (EPS) conversions have become somewhat common in the last few years as an easy way to add power steering, or to keep it when an engine swap might make keeping the stock power steering system difficult. The system from the 2007 Toyota Yaris is one that is often used, as it requires no special inputs to function, although it will benefit from a speed input. And unlike later units that get their speed signal only over the CAN bus, the Yaris steering ECU has a separate input for speed. Others have done this conversion by cutting the MR2 steering column and grafting the Yaris motor to it, but I chose to take a different route, replacing the entire MR2 column with the Yaris column.

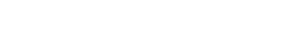

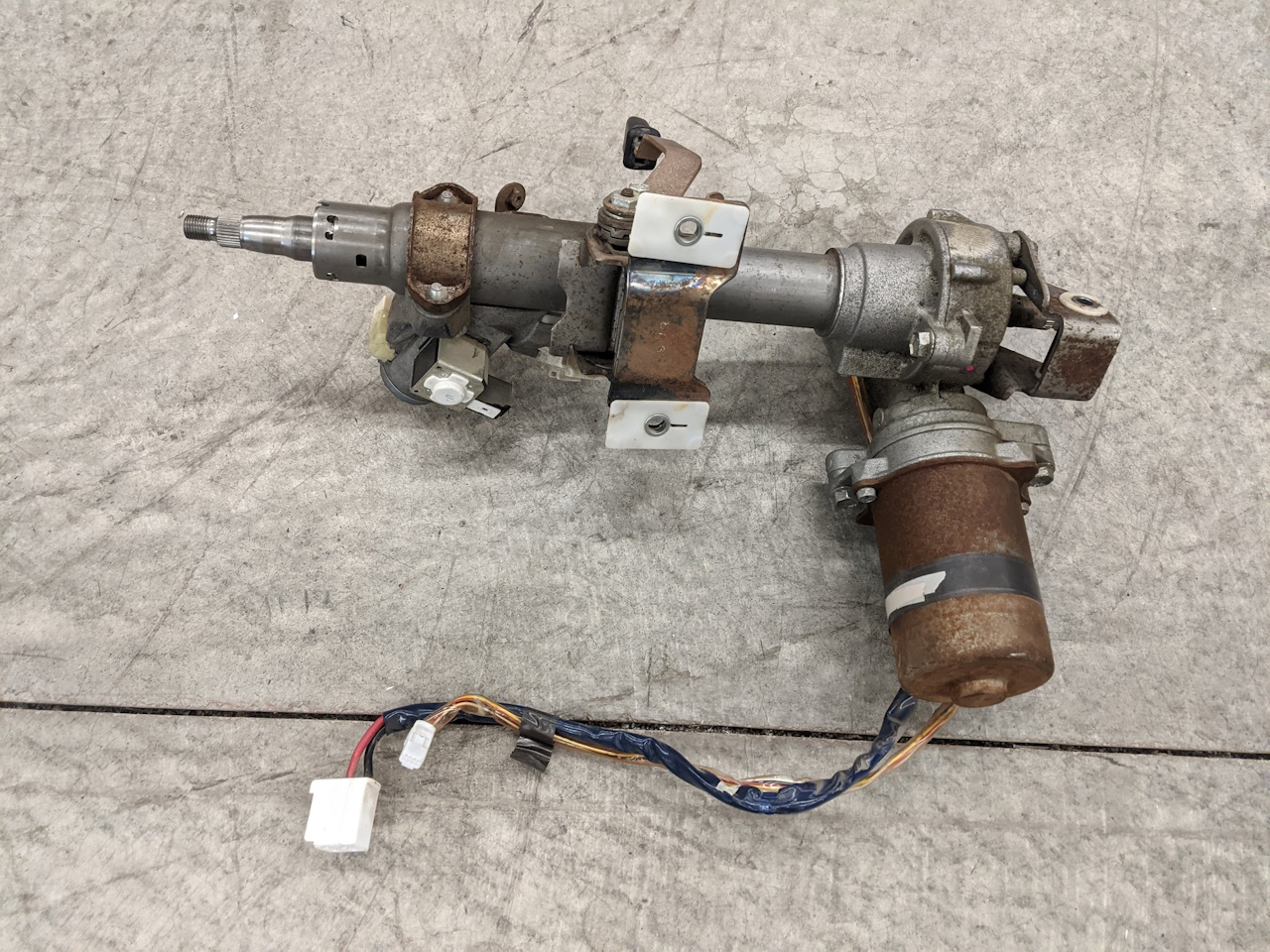

The Yaris column as I received it

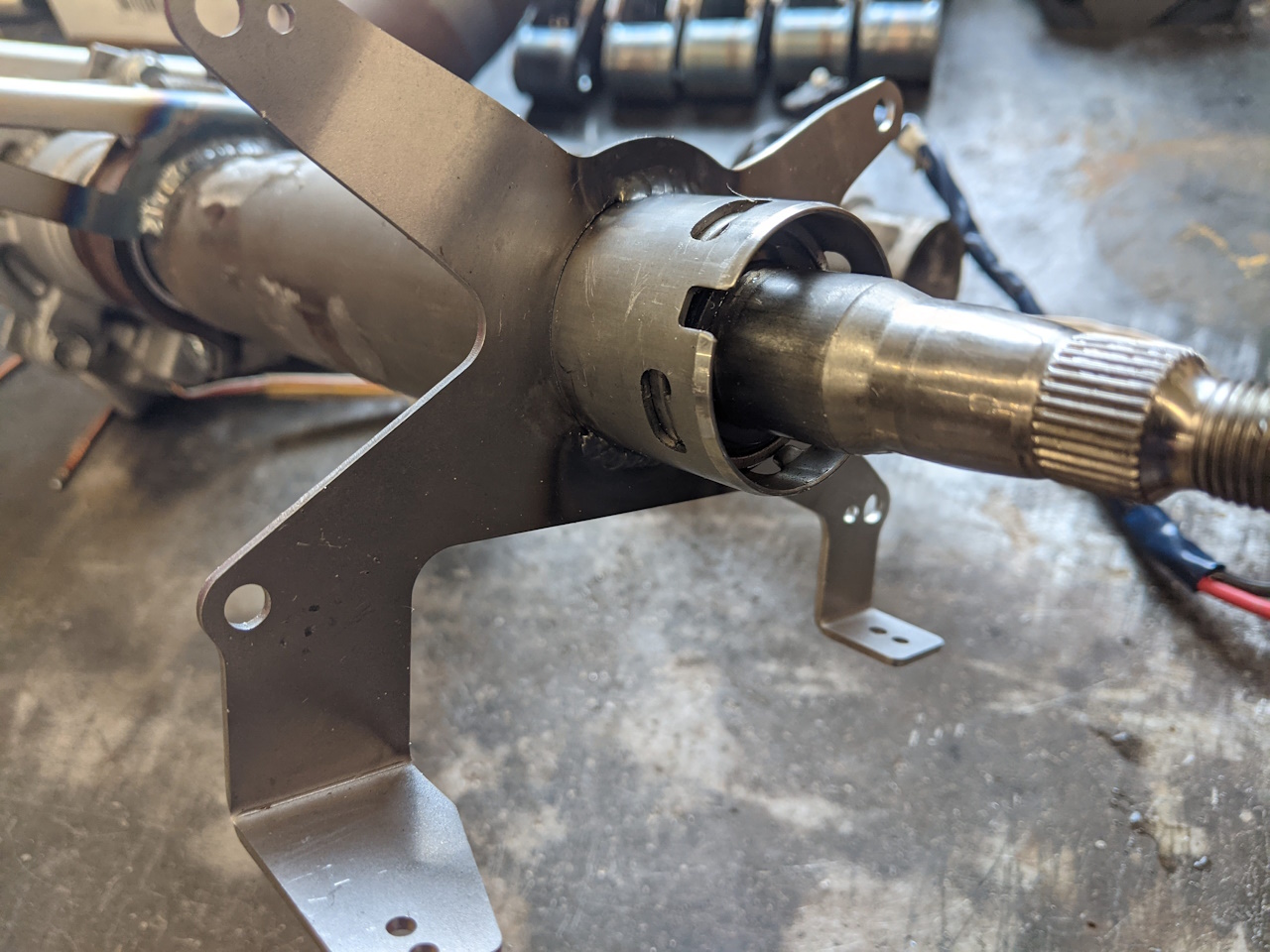

Mounting the Column

I test fit it initially with a mocked up bracket that kept the Yaris tilt mechanism, but immediately found that it sat way too low this way. This would have allowed me to keep a small amount of height adjustment, but my normal steering wheel position with the MR2 tilt column happens to be with the column perfectly straight anyway, so I won't mind losing the tilt mechanism.

Yes, I am also in the middle of a removing all the extra wires from my dash harness for systems that I don't need / don't have. Between power locks, security system, and a few other things, there was nearly 5lb to be saved there! But that's another topic...

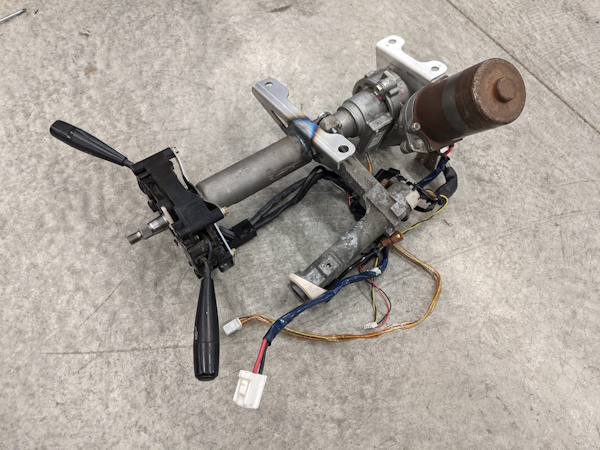

In order to fit the steering column, I had to notch the dash cross bar. Shown below is the initial notch to fit it for my initial test.

I went through several iterations of mounting brackets and ended up clocking the motor to a lower angle than it sits at in the Yaris, so my notch ended up a bit larger than necessary.

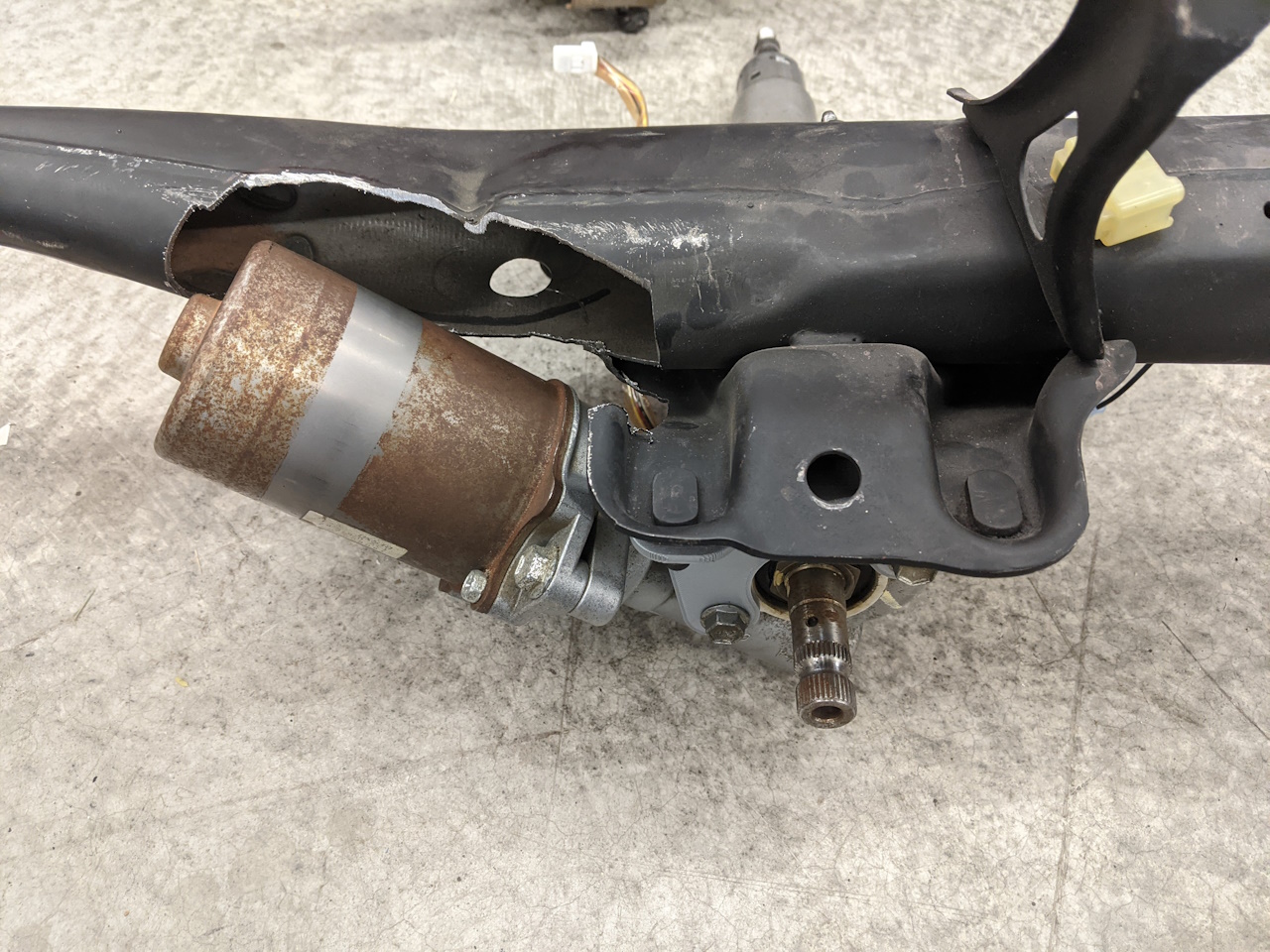

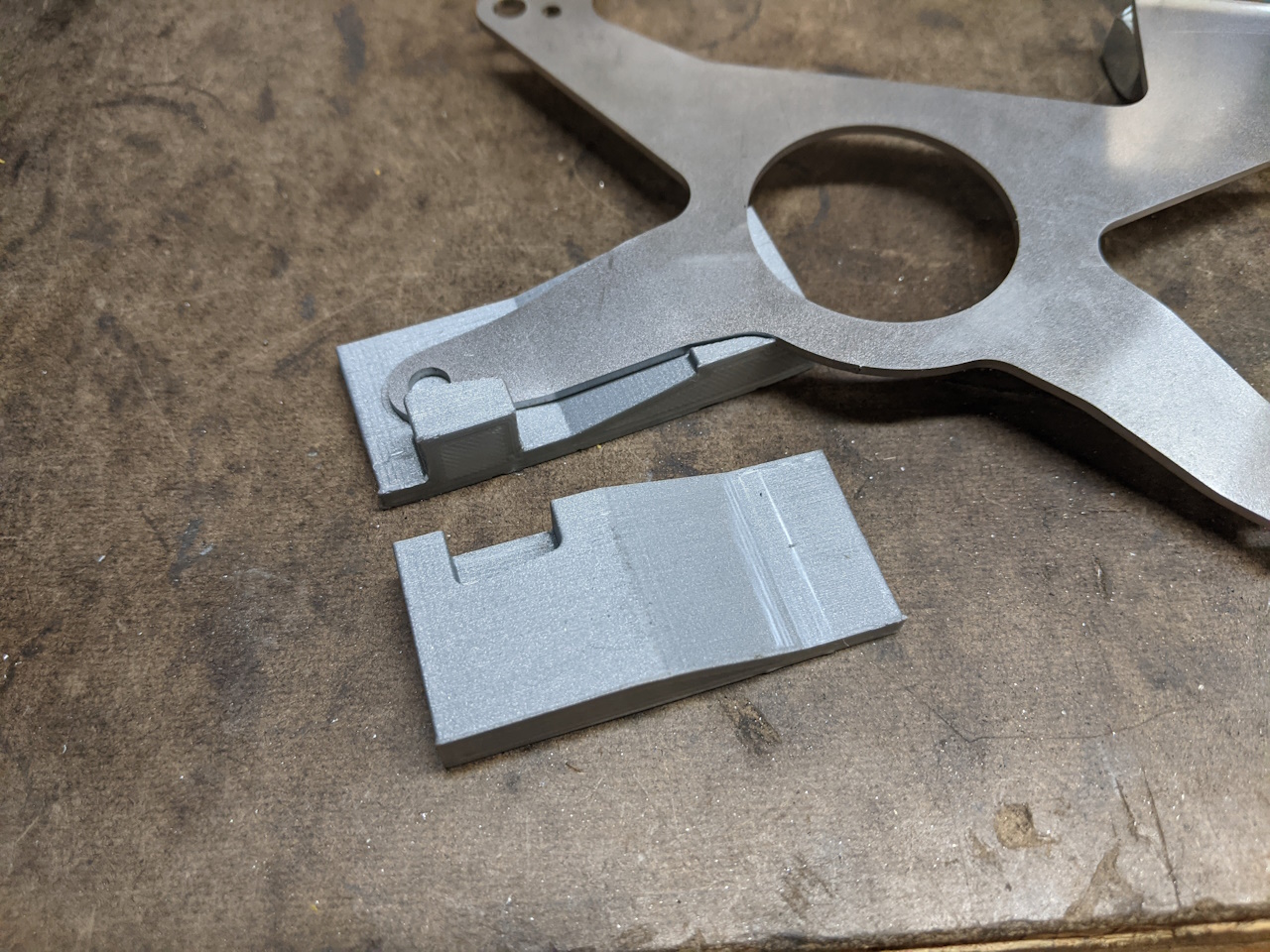

3D printed mockup of my final bracket design. The forward one will be aluminum, the rear one (closer to the driver) will be steel so that it can be welded to the Yaris column.

Combination Switch

To mount the stock combination switch and steering column shroud to the Yaris column I drew up a bracket and had it laser cut and bent. To match the stock shape, I 3D printed a joggle die to use with my arbor press. It worked extremely well and created a pair of bends that would have been difficult to bend otherwise due to lack of a good reference on the part.

Perfect fit to the stock combination switch.

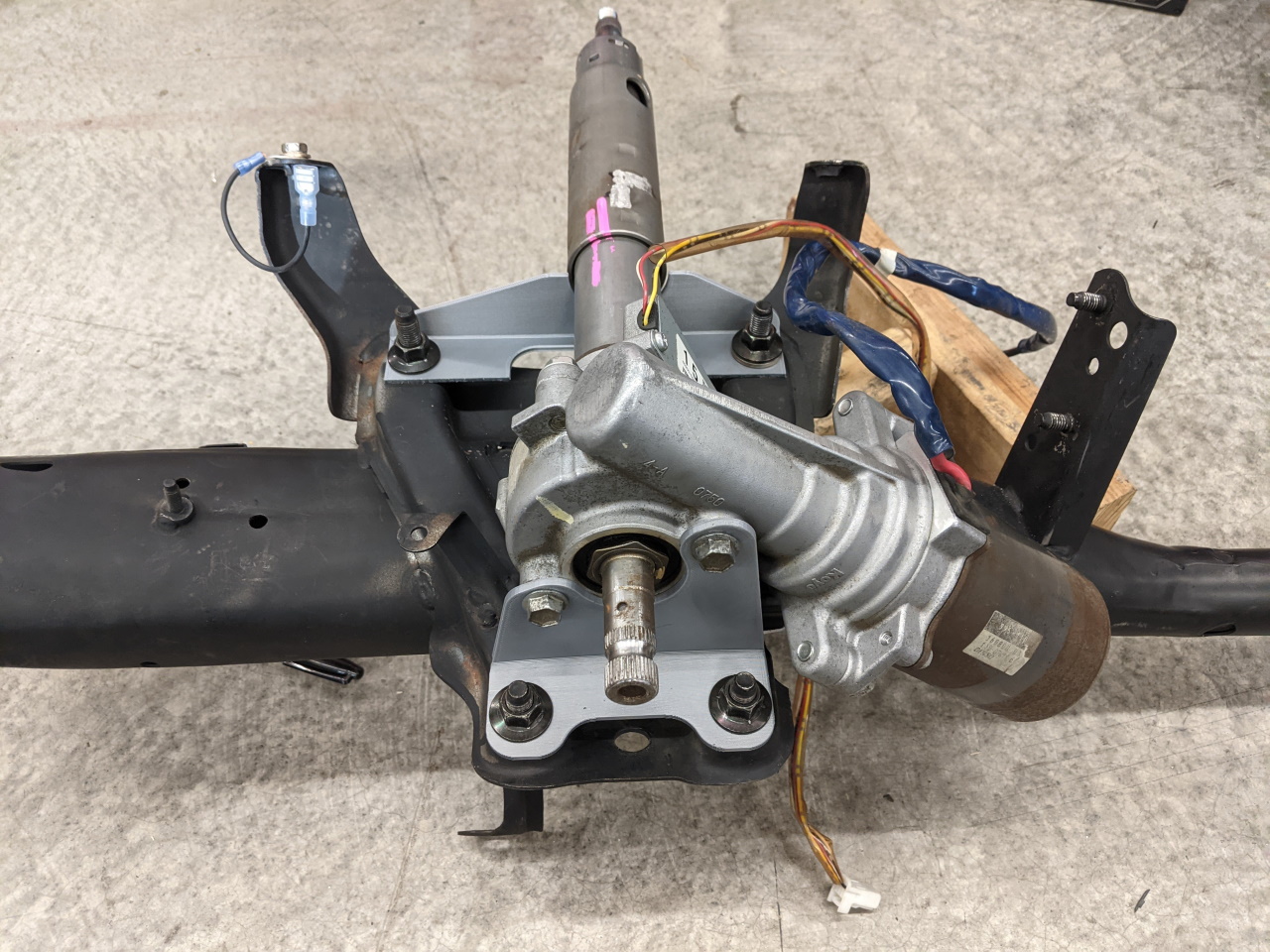

Here are the two brackets welded to the Yaris column. The Yaris column is two pieces and the motor can be clocked relative to the upper part. But both of the welded brackets are on the upper part, so care must be taken to align them before welding, or the combination switch will end up crooked. Unfortunately it turns out that mounting the stock column shroud on only 2 out of 3 mounting points allows it to move too much, eventually breaking the 30+ year old plastic around the mounts. It was probably starting to fail anyway. For now I'm just running without the shroud. The smooth Yaris column, once painted black, is so much cleaner looking that the bulky MR2 tilt mechanism that the lack of the shroud doesn't look too bad. At some point I may add another bracket to the column for the third mounting point.

One last step to the combination switch is the plastic thing (I'm not sure what to call it!) that interfaces with the steering wheel and the auto canceling turn signals. It's too long to fit with the end of the Yaris column. I trimmed it shorter as shown below, and while it's a little trickier to install, it works perfectly.

I'm afraid I didn't take any good pictures of it, but I mounted the stock MR2 ignition cylinder to the Yaris column so that it is positioned in the stock MR2 location. The Yaris column is a bit smaller diameter than the MR2 column at that location, so I used the ignition cylinder bracket and my arbor press to form two pieces of aluminum into circular shims to take up the gap. The stock security bolts of course had to be ground out to remove, and they were replaced with normal screws. I also had to remove the steering lock, but that's not a bad idea for a track car anyway (and usually a required mod on race cars).

Steering Shaft

The Yaris steering column has a larger spline on it than the MR2 column, and is shorter. So a custom longer steering shaft is required. I purchased a Yaris steering shaft shown here next to the original MR2 shaft. I cut both, and welded in a section of 1" DOM steel tube. The collapsible lower portion of the MR2 column is retained this way.

Wiring

I took the cover off of the Yaris steering ECU and pop riveted two aluminum brackets to it so that the ECU could mount in the stock MR2 air bag ECU location. Perfect fit, and well within reach of the wires from the steering motor, but obviously not an option for someone who still has the stock air bag.

The wiring on this project is fairly straight forward. Connect the motor and torque sensor from the column to the ECU and supply power, switched power, ground, and a speed signal to the ECU. I hunted high and low for a source for the required connectors and the only source I could find was a $40 kit on ebay. Expensive for what it is, but it was the best option I had. If you pulled the parts yourself from a junk yard and could get the ECU pigtails, that would likely be more cost effective.

I repurposed the 40 amp AM2 and it's associated wire to power the EPS system, and rewired the engine bay fuse box to source power from the alternator connection in the fuse box. You could of course run a new wire from the battery or front fuse box with a new fuse for the EPS system. Switched power and the speed signal I tapped into in the dash (remember I had that harness all torn apart at this point anyway).

The Yaris wiring diagram can be found here. I also referenced the pinout diagram on this page quite a few times.

Initially I only connected power, switched power, ground, and speed. This works fine, although the steering will not turn on until the ECU detects a speed signal. I did eventually tie it into the CAN bus for the 2GR ECU, and it seemed to improve the steering feel a little. I'm not sure why, and maybe it was my imagination, but it seemed just a little lighter and seemed to return to center better with the CAN bus hooked up. It also allows the EPS to function whenever the engine is running, instead of just when the car is moving. If you have a modern Toyota engine swap and can hook the EPS into the CAN bus, I would recommend it, but it's not necessary.

It is also worth hooking up a wire to the TS pin. Normally it would run to the OBDII connector, but I just have mine loose under the dash (covered of course). There is a zero point calibration process on the torque sensor (ground pin TS for 7 seconds with ignition on) that helps with steering feel and self centering.

Final Thoughts

The primary goal here was weight reduction, so how did I do? The stock MR2 tilt column is 15lb. The Yaris column with new brackets and the EPS motor included was 15.5lb, so that means that nearly entire weight of the stock power steering system (23lb) is saved, less the weight of the Yaris steering ECU (1.5lb). So the total savings was 21lb. Not bad.

Steering feel is, in my opinion, pretty good. It's not excessively light or over boosted. At low speeds it doesn't return to center quite as well as I would like, but I'm not sure my car has ever had great self centering at low speeds so I'm not sure I can blame that on the EPS. I'm not sure why. At this point I have not touched the stock power steering rack, other than to loop the lines to allow air to travel from one side of the rack to the other to reduce resistance. Taking the rack apart to remove seals and maybe weld the spool valve in the pinion might be a project for the future, but I'm hesitant to do anything that would prevent me from going back to hydraulic power steering, just in case I find some issue with this system when I get a chance to test it on the track or autocross course.

The only downside I have found so far to eliminating the tilt column is that it's impossible to remove the gauge cluster without dropping the column a little, so some interior projects take a few minutes longer. But it's a pretty minor inconvenience.

If anyone wishes to do the same please contact me. I'm happy to make a small production run of the brackets for the steering column.