The "new" MR2 that I bought to replace my wrecked one was in rough shape. Really rough. But, I had some major plans for this car, and I wanted something I wouldn't feel bad cutting on!

It had a partially installed (not running) Camry 5SFE to replace the stock motor that the previous owner blew up, two badly done previous paint jobs, a bunch of holes in the trunk lid from various wings that previous owners had mounted, a trunk full of parts to finish the engine swap, and a pretty rough interior. Given all that, I think the $1200 I paid for it was probably too much. But I needed a chassis and this was the cheapest one I had found that was somewhat close to home.

I wanted to fit wider wheels and tires. And I wanted an "almost stock" look at the same time (at least on the fenders).

The following is a bit of a photo montage of the process, which was was documented in some detail on the forums:

MR2oc.com: Cutting, Flaring, and Welding Stock Fenders

MR2.com: Cutting, Flaring, and Welding Stock Fenders

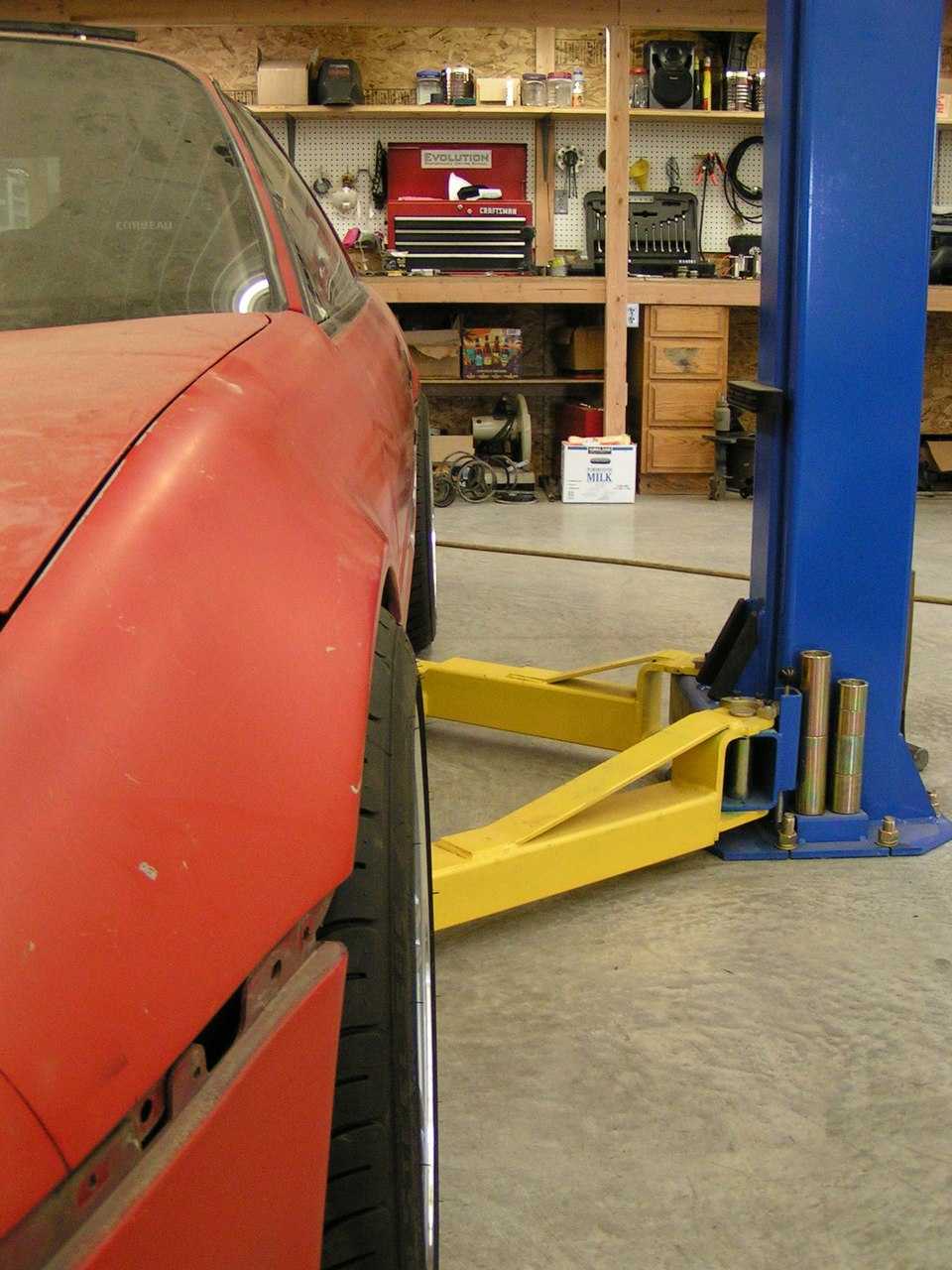

Initial test fit of 17x9 and 17x10.5 wheels / tires:

Cleaning off the paint:

Drilling spot welds on the rear fenders:

Starting to cut!

Welding in filler pieces

Test fit with wheels and tires. Shaping up pretty nicely!

Test fitting bumpers, side vents, and side moldings.

Testing tire clearance at max compression.

Welding it back together.

Grinding the welds flush.

More welding and grinding.

This brings us more or less to the end of the cutting and welding portion of this project (about six months worth of evenings and weekends). Next up, paint prep and paint.