Back in 2018 I published a short article about oil pressure on the 2GR-FE, and since then I have offered an oil pan baffle for sale. That baffle helped, but I always felt that the oil control solution could be better, hopefully without the expense and complexity of a drysump. In 2025, I finally revisited the subject.

The Problem

As discussed in my 2018 article, the 2GR-FE has a bit of an oil control issue on right hand corners. The sump occupies the RH half of the engine, while the LH half has a raised and mostly flat "upper oil pan" that provides clearance for the exhaust. Most transverse engines are similar in this respect. On RH corners, oil tends to flow out of the sump and up into this upper pan leaving the sump empty enough that the oil pickup can suck air instead of oil. In the past I had demonstrated this with the approach of taking LOTS of data and doing scatter plots vs g force and plotting trend lines. This was useful, but I found it to be somewhat limited as well as it doesn't provide the level of detail that I found was needed. I also had to either ignoring the effect of RPM, or filter the data to a relatively small RPM window to mitigate the effect of RPM. This time I took a different approach. First I produced an RPM vs oil pressure equation that allowed me to calculate the expected oil pressure at almost any RPM, and then compared that to the pressure data from a single autocross run plotted against time. This allowed me to see exactly when the pressure was dropping, how much, and for how long.

All of the data presented here was logged at 50hz with my Race Capture/Pro, except for some of the old data from 2018/2019 which was logged at 10hz. 5w30 Mobil 1 was used for all tests. In general I tested with standard oil level for the first half of a day of autocross, then added a pre-measured half quart at lunch to see the effect of that slight over fill.

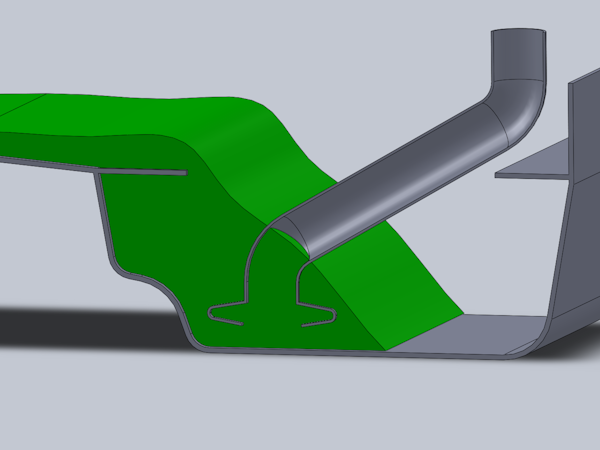

The first question is, how much oil pressure should we have. The graph below shows oil pressure vs RPM for a "slow" (roughly 1/3 throttle) 2nd gear street pull. I did this test at partial throttle both to get more data, and also to avoid effects of acceleration g forces.

One thing to note here is that there is a significant increase in scatter in the data starting at about 5000 rpm. I am not sure why. Perhaps a bit of oil pump cavitation, although this seems unlikely. Oscillations in the pressure relief valve maybe?

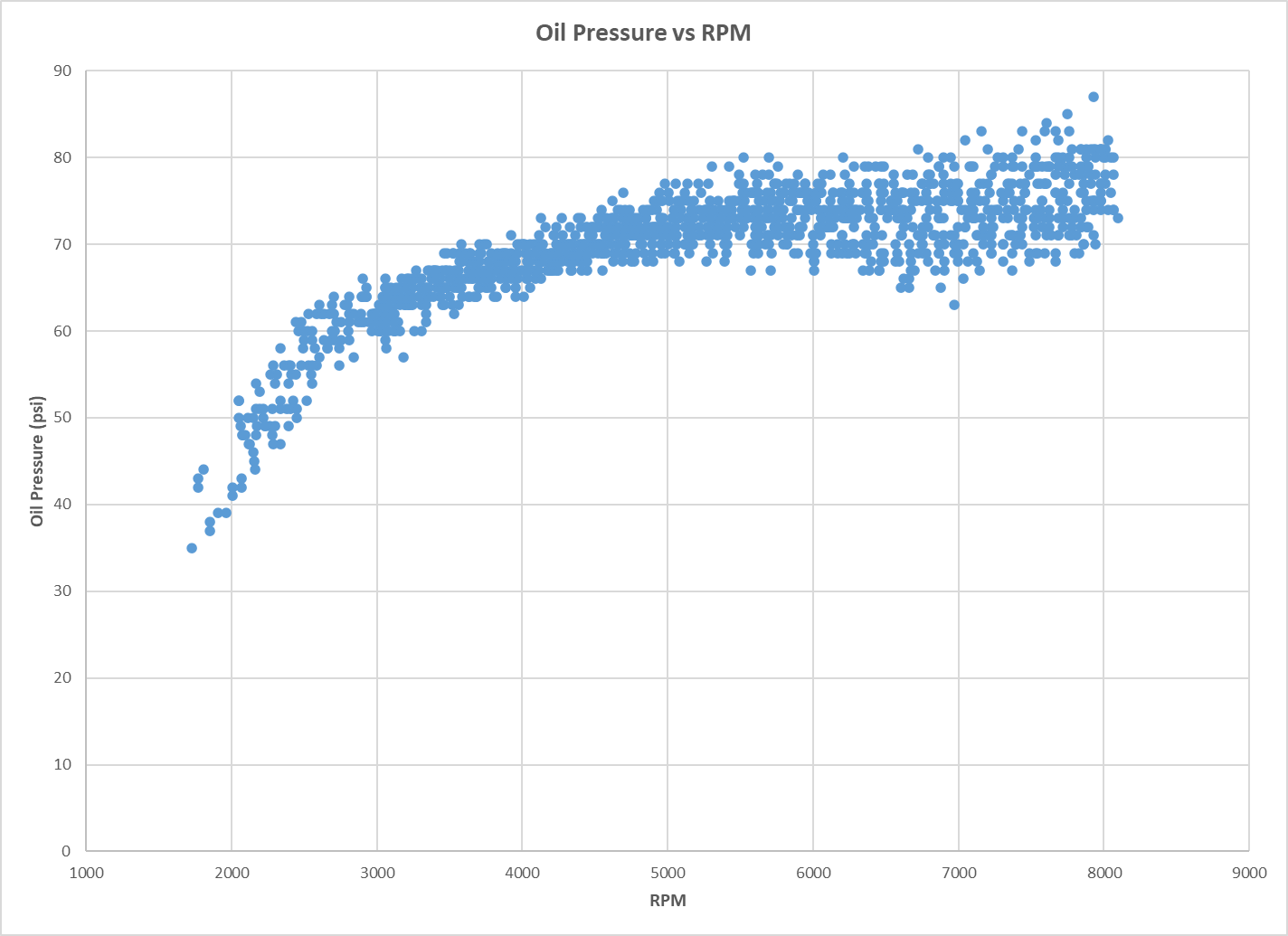

With smoothing enabled in the data logger a much nicer data set is generated, and a curve can be fit to it in Excel.

I then used the resulting equation to predict the oil pressure at any RPM. The graphs that follow use this method to generate an "oil pressure deviation" value, which is the difference between the actual measured oil pressure and the pressure predicted by the curve fit equation. I adjusted the constant term of the equation for each graph to compensate for temperature variations.

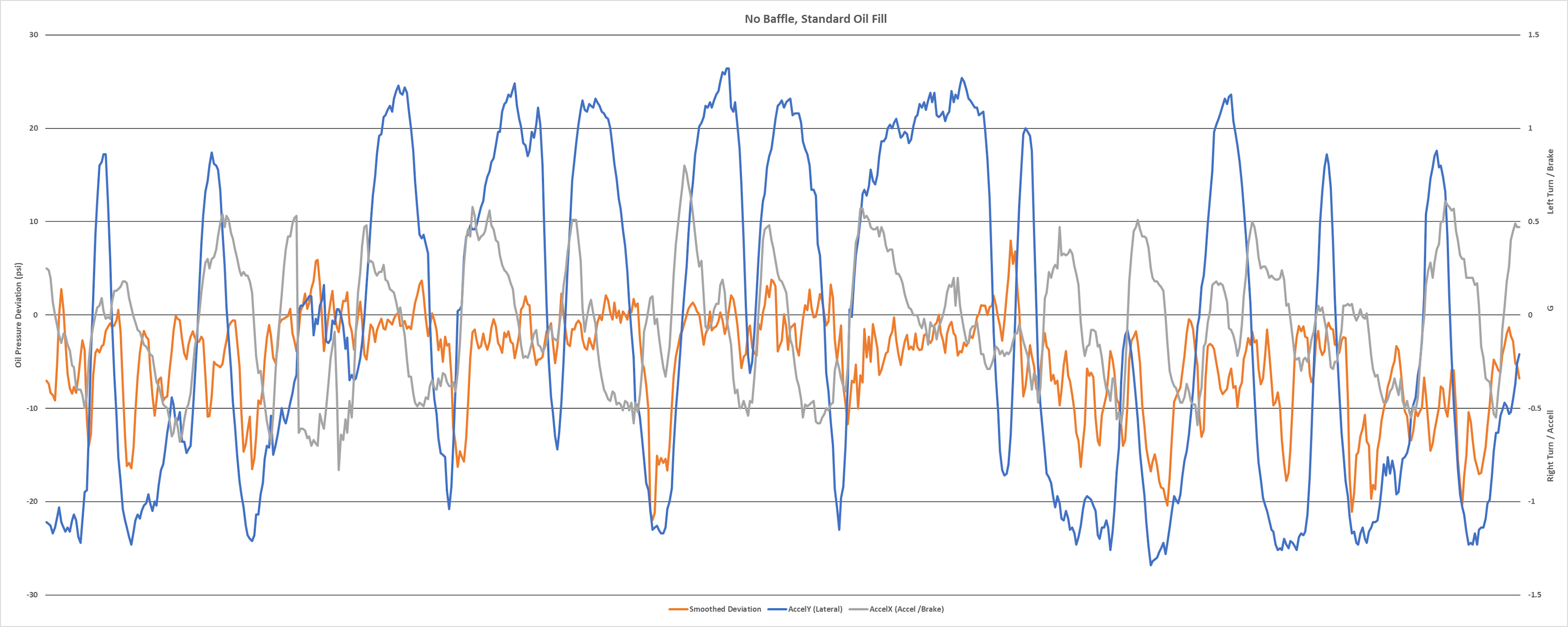

Applying this method to some of my old data from 2018/2019, the graph below shows the oil pressure deviation along with g forces that I have recorded without any baffling. As noted above, these old logs were only recorded at 10hz. As such I didn't apply very much smoothing to them as there really wasn't enough data to smooth a lot without losing significant resolution. Note that the bulk of the dips in oil pressure (orange line) occur during right hand turns (blue line below zero). There are a couple of things to look at on these graphs. The number of drops, how far down it drops (a drop of less than 10psi from expected is hardly significant while a drop of 20 or 30 psi is quite a lot), the duration of the dip / how fast it recovers, and how long normal pressure is sustained after a turn begins (this will be easier to see in later graphs with better data).

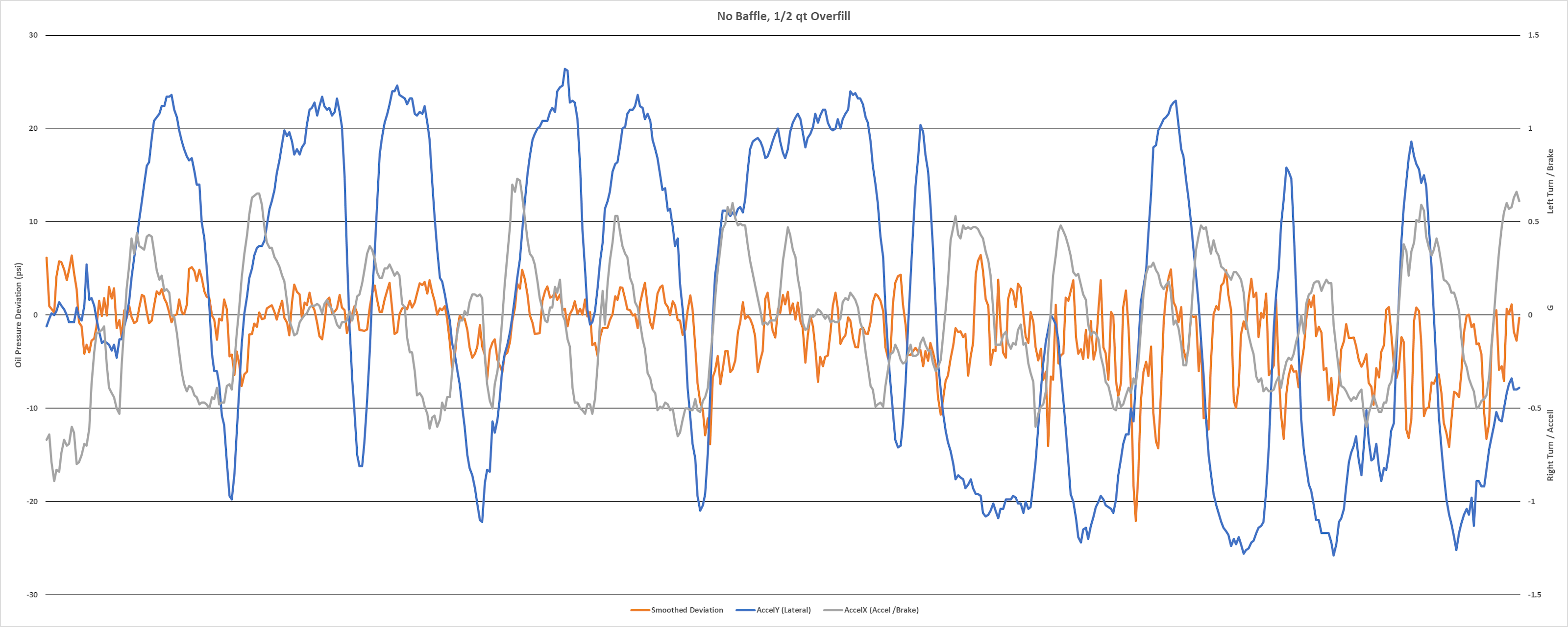

Adding an extra 1/2 quart of oil to the pan helps a little, but there are still plenty of dips in oil pressure.

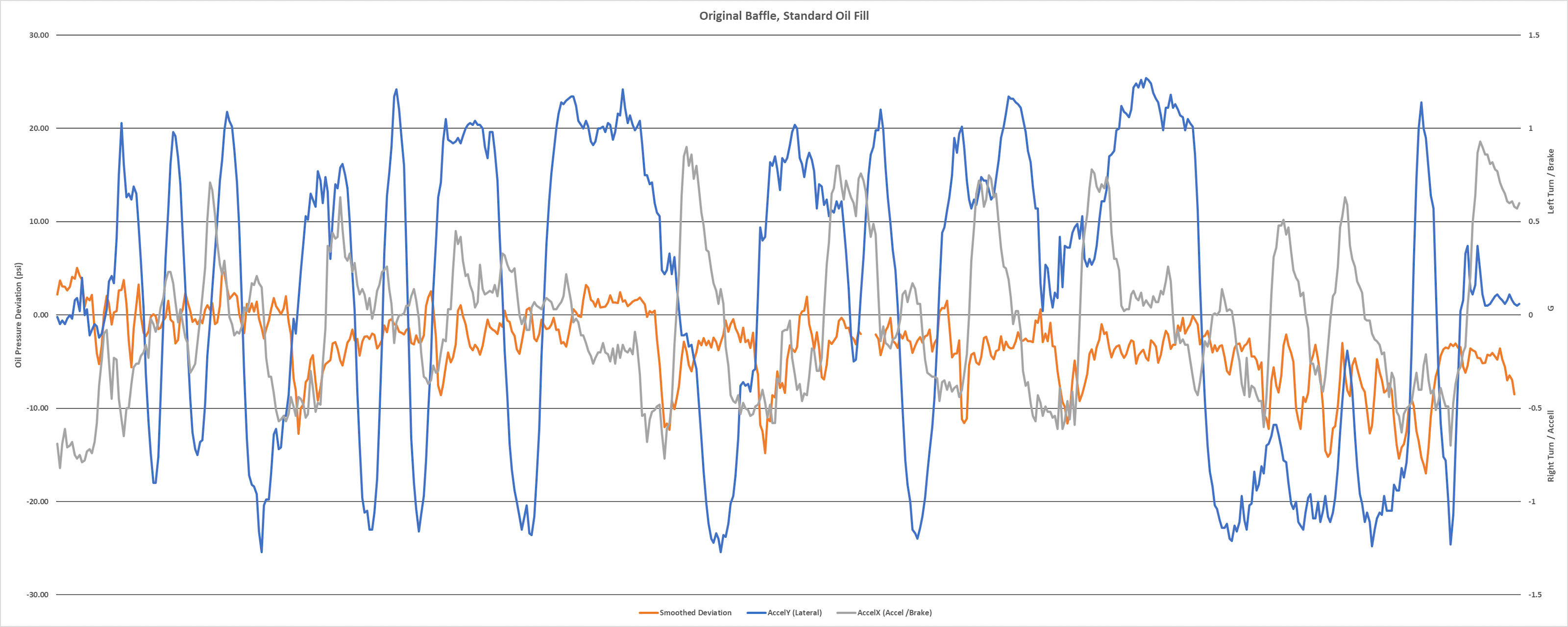

My original baffle design helped (note that this is at standard oil fill level), but I always felt that it could be better.

Improvements?

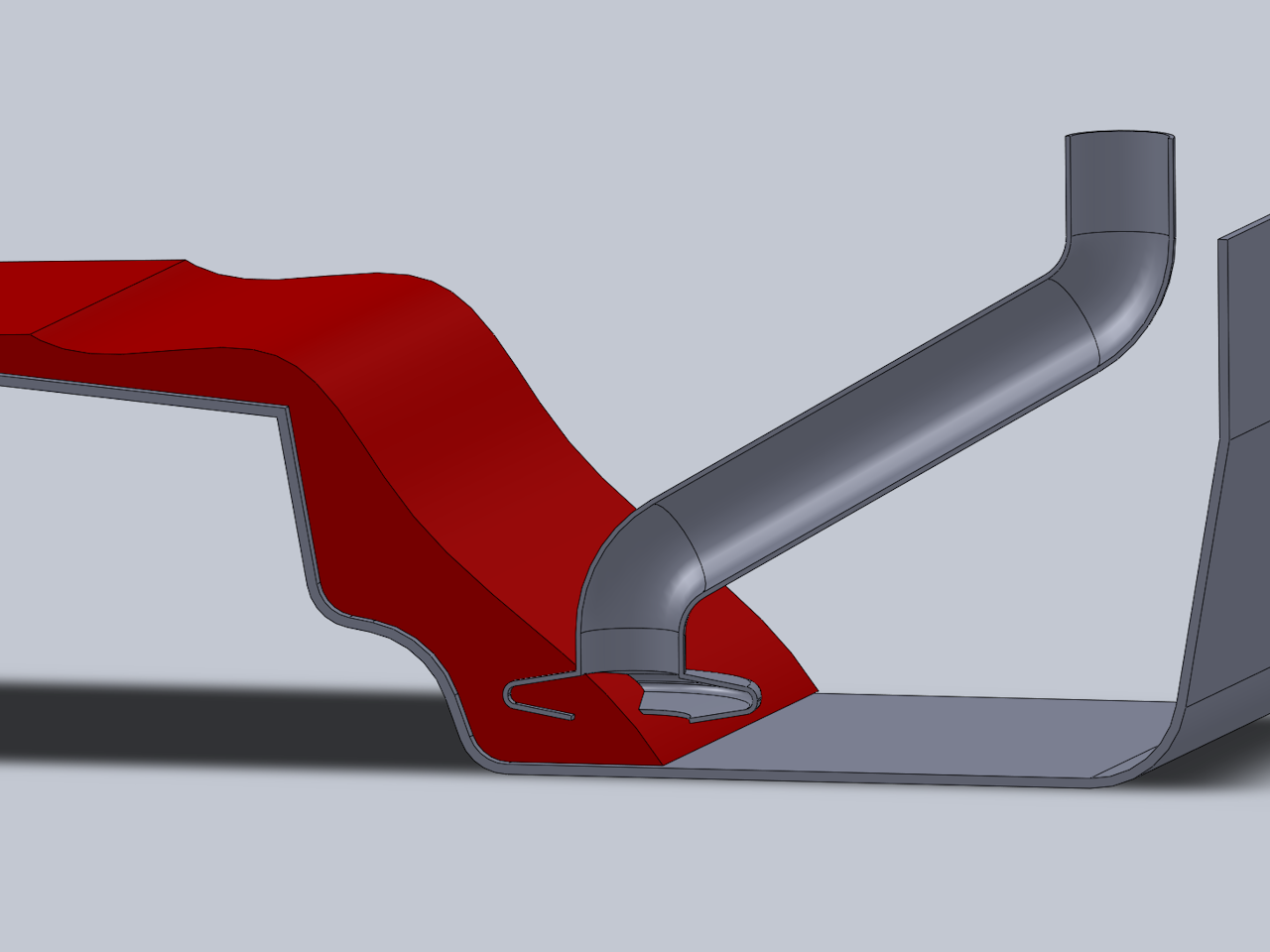

Over the winter of 2024/2025 I set out to improve on my original baffle design. I had spent a fair amount of time back in the 2018/2019 time frame testing different iterations and hadn't come up with anything significantly better, but I figured I would give it one more try. This one ended up being baffle version 7. I added lowered all of the rubber flaps closer to the bottom of the pan (this was going to require removing the small stock baffles from the pan), added a couple of additional baffles to try to direct oil towards the pickup and reduce slosh, and generally improved the fit. It looked really good. Interestingly, the layout of baffles looks very similar to the weld pattern in the Lotus baffle in the "red" oil pan (keep this fact in mind...).

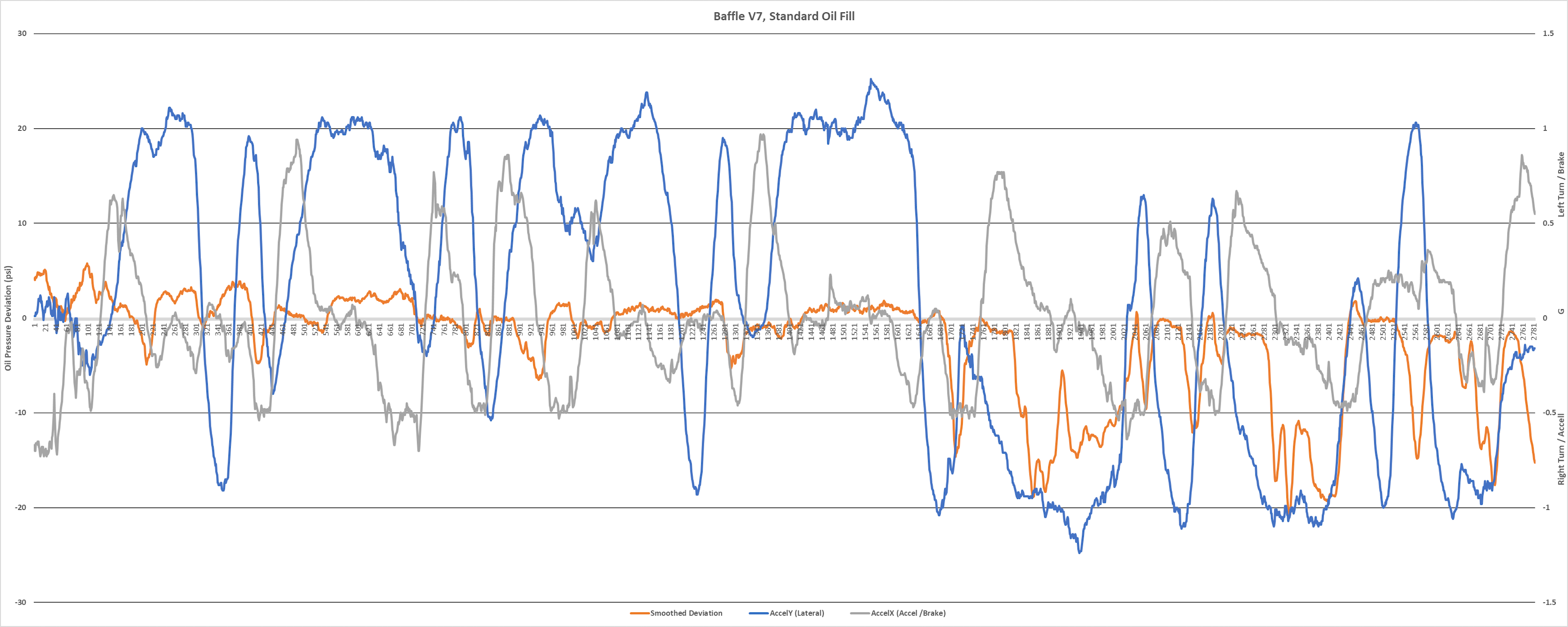

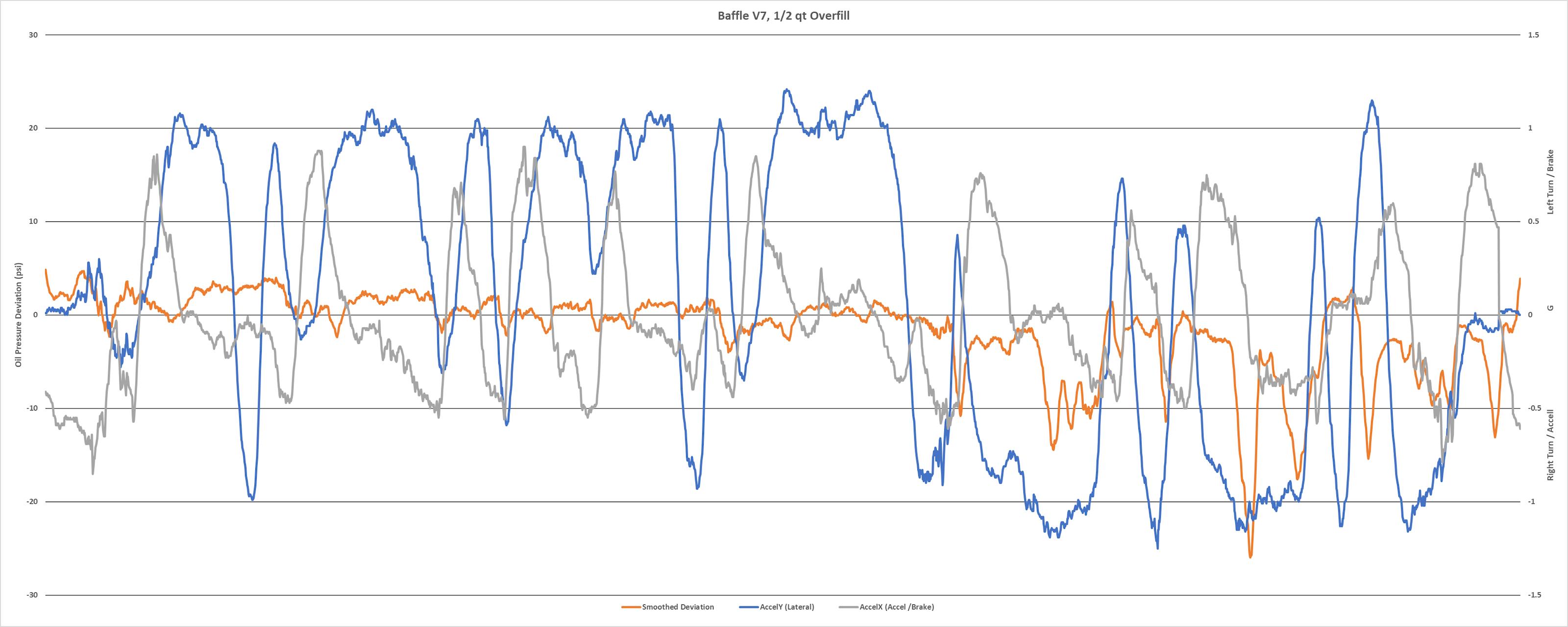

When I tested it however, the results were... disappointing to say the least. Lots of oil pressure drops still, and sustained drops as well. Not only does it dip on hard LH corners, but on several of them the pressure does not recover until the corner is over. Note that this is with the newer higher logging rate and smoothed data. The smoothing does reduce the depth of the dips slightly (a few PSI), but also increases with width of them slightly. Overall it just makes the graph much easier to read.

Adding an extra half quart of oil helps a little (it always does), but the results are still not great.

Back to the Drawing Board

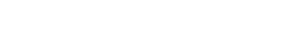

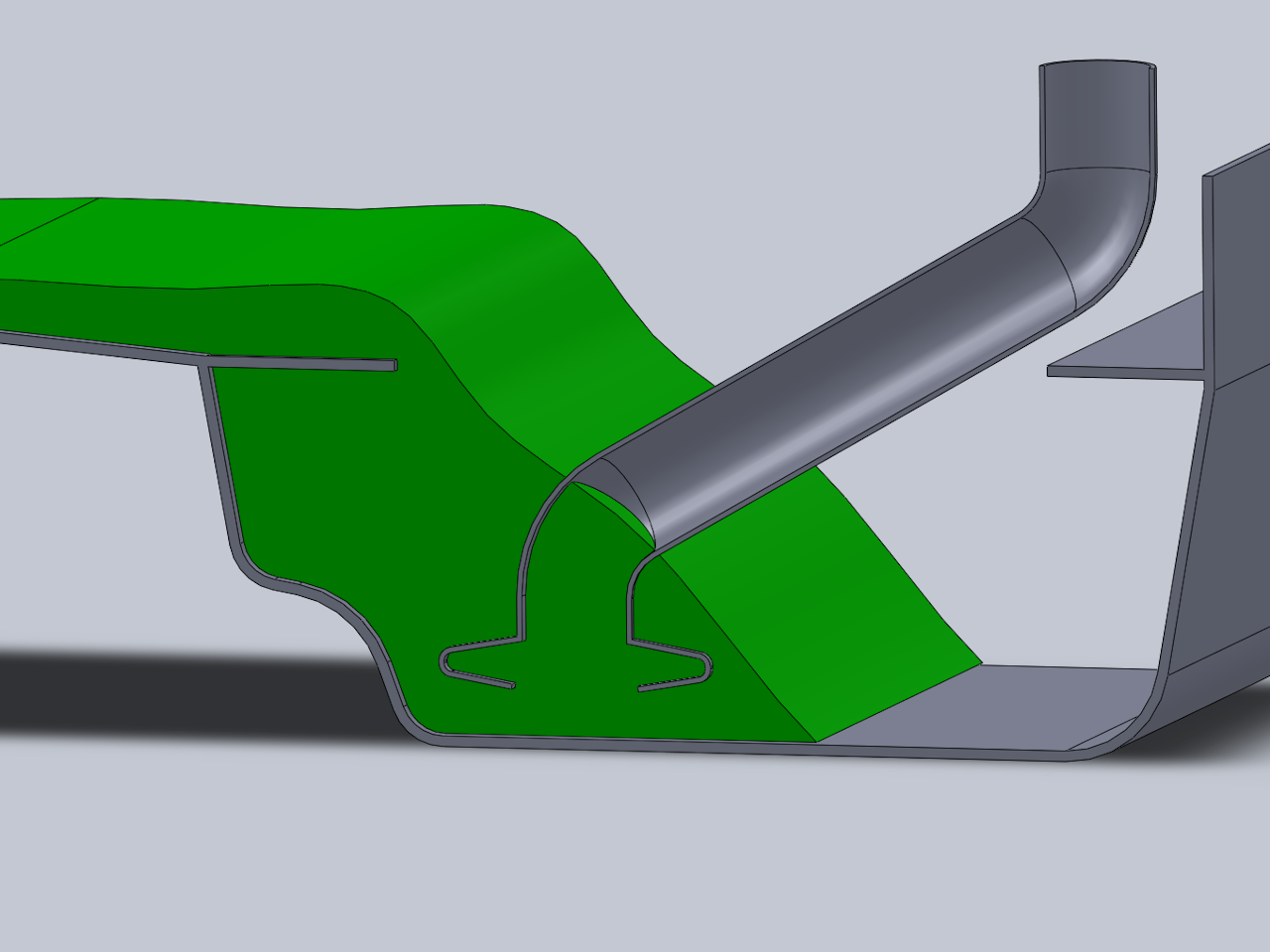

So what is going on? My best guess is that I had restricted the flow of oil back to the pickup such that it was emptying the sump and the oil couldn't get back quickly enough. So if more baffling was not the answer, maybe less baffling is. I decided to revisit something that I had briefly experimented with back in 2018 and discounted as "too simple". That design, which I have taken to calling the "splash ring" is a flat plate that fits between the upper and lower sumps and protrudes about an inch and a half into the pan horizontally.

At 1g lateral, the oil in the pan is experiencing 1g of downward acceleration due to gravity and 1g of sideways acceleration from cornering. Equal forces in each direction will cause the oil to attempt to achieve a 45° angle in the pan. At 1.2g that angle is increased to 50° from horizontal and at 1.4g to about 54°. Due to the design of the 2GR's oil pan(s), this causes oil to flow up into the upper pan and away from the pickup. Below is a rough mockup of the situation that results from this. Obviously this is a simplification as there is also a constant flow of oil back into the pan from various sources, but more or less this is what is happening at 1g+.

Adding the "splash ring" protruding into the pan at the joint between the upper and lower pans shifts that 45° angle over, keeping the pickup submerged without restricting the flow of oil back to the pickup.

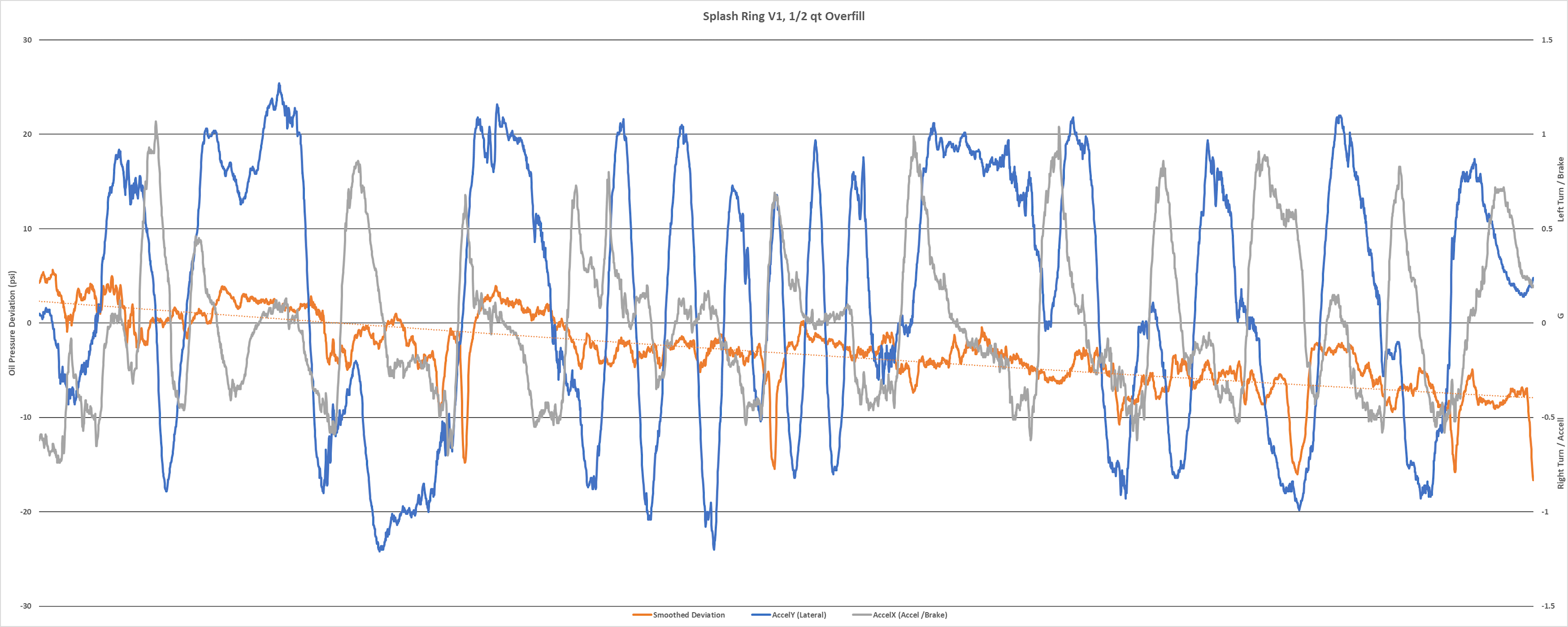

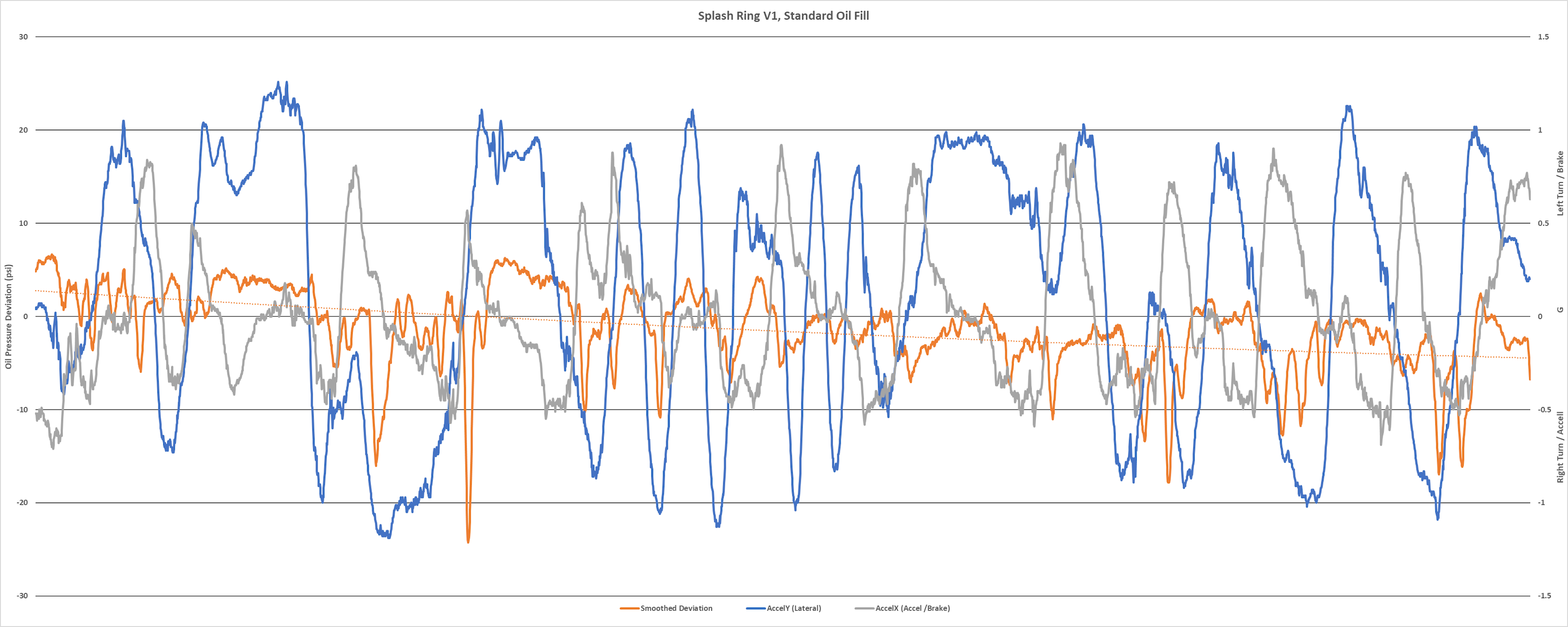

I started with a relatively small ring, plus two baffles that protruded up into the upper pan to try to capture the oil coming from the two drains there and prevent that oil from flowing left into the upper pan. See this blog post for a deeper dive on the 2GR oil drains. Initial testing of this design was quite promising. A couple of dips in pressure, but note that it recovers quickly from those dips AND several of those dips seem to correlate more to hard braking (or the combination of braking and cornering) than to cornering alone. This does make sense as I have removed the bulk of the slosh protection in the forward direction. Adding an extra half quart of oil makes it look even better.

Note that there is a general downward trend of oil pressure throughout the run. I have noticed this in a lot of this data, and I have included a trend line on some of the graphs to highlight this fact. I suspect it is due to oil temperature effects.

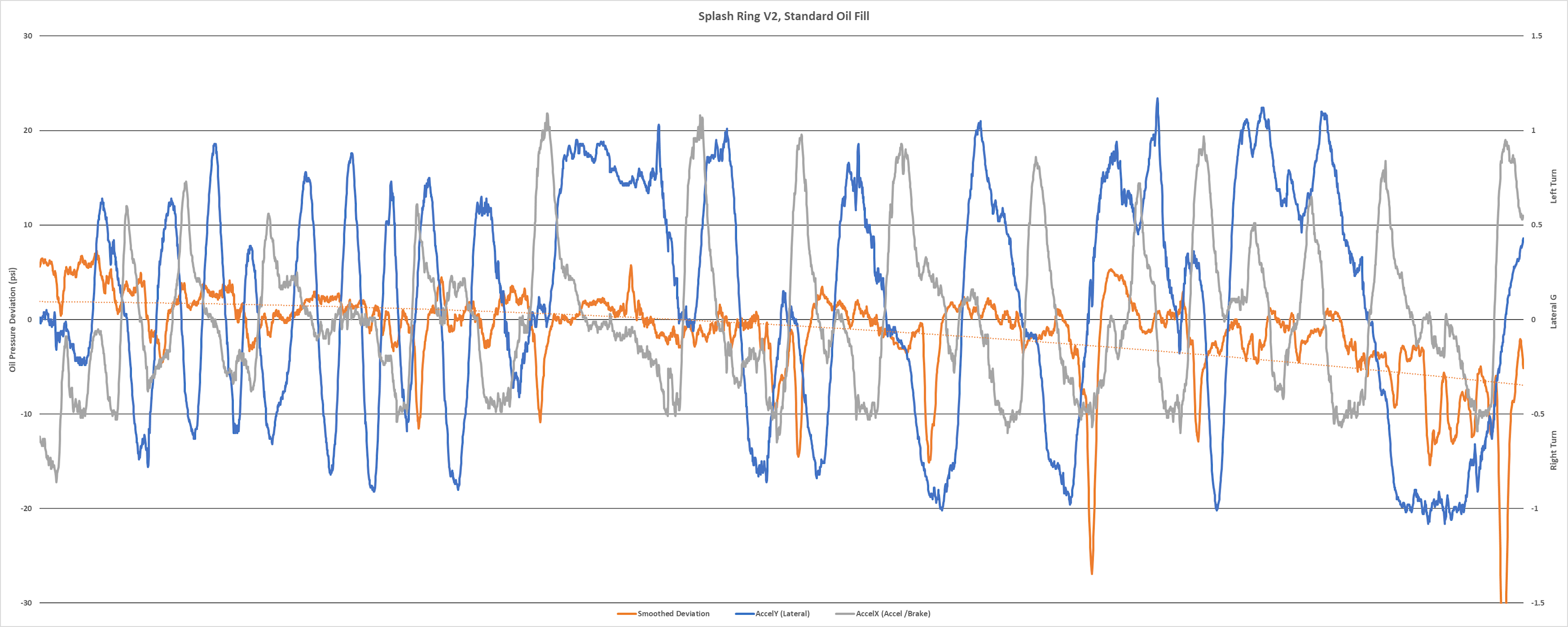

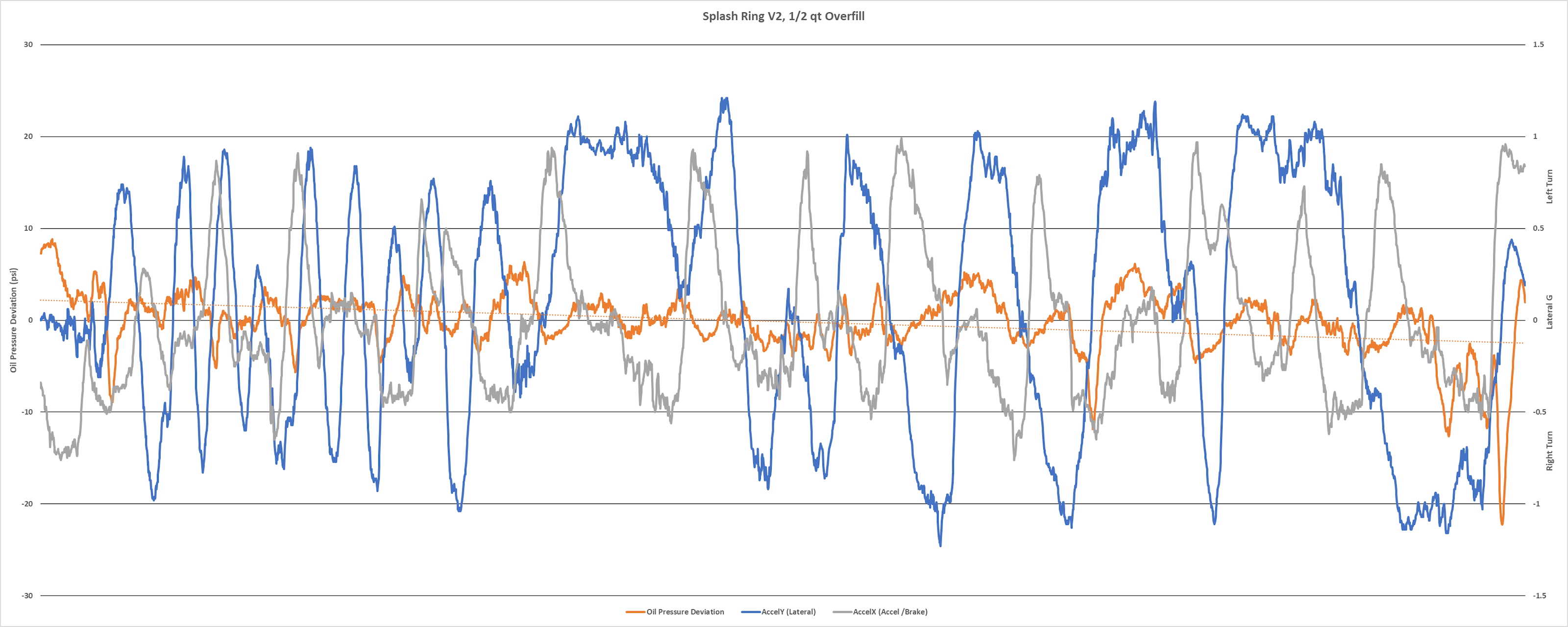

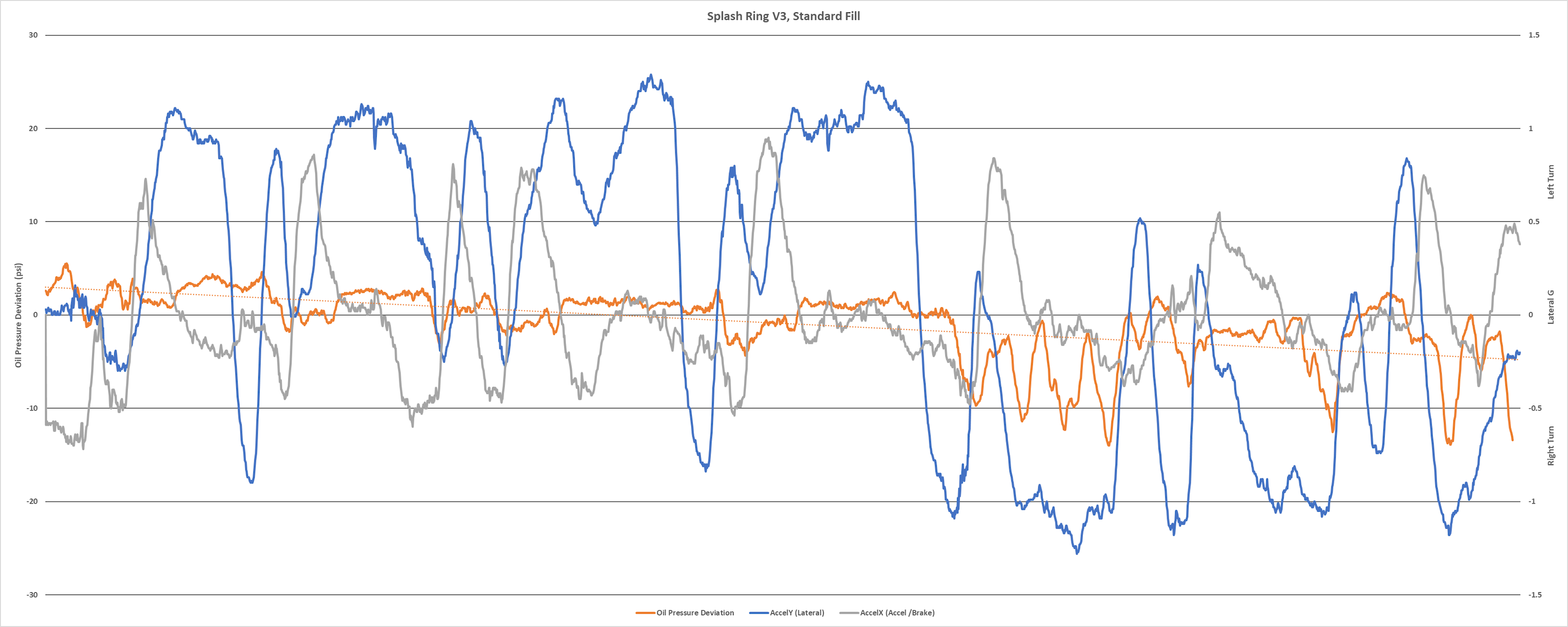

Splash ring versions 2 and 3 increased the width of the ring, first along the left side and then around the front of the pan. Version 2 also introduced a lateral baffle extending down into the pan to hopefully help reduce the forward slosh under braking. With standard oil level the dips under braking are still present, but cornering performance is getting better. As always the extra half quart improves everything.

When I went to test V3 I screwed up, and didn't realize until later. As I said previously, my testing process was to run standard oil level for the first half of an event, then add a half quart for the afternoon. After the event I was analyzing the data and it overall looked like a big step backwards and I couldn't figure out why. Then I discovered the dipstick showing standard oil level instead of the half quart over fill. Somehow I had run the first half of the day a half quart LOW, and then added up to standard. Oops. I won't even share the half quart low data so as not to confuse the issue, but lets just say it looks worse.

New Oil Pickup

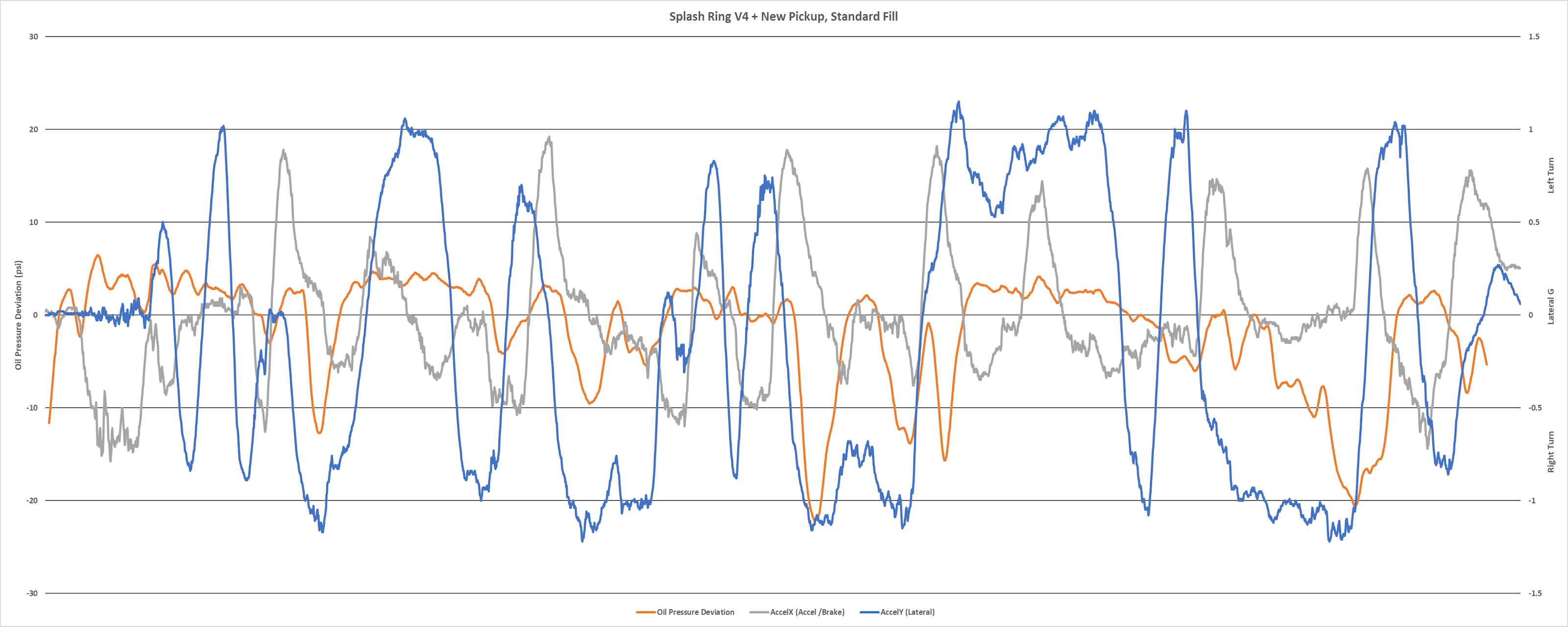

At this point I was pretty much out of ideas for improvements to the baffle without going back to something closer to my original design which I didn't want to do. I made one last adjustment to the baffle, increasing the length of the lateral baffle that was intended to help braking so that it reached about 2/3 of the way down into the pan, and at the same time installed the modified oil pickup with the rubber foot that I had prototyped several years ago. I had waited to install it until I had time to do sufficient testing and due to various personal reasons I had taken a couple of years off of autocross so no testing was happening. The theory here is that the rubber pickup can sit much closer to the bottom of the pan so it should be more tolerant of lower oil levels.

The initial test with this pickup at standard oil level actually does not look very good, and unfortunately I'm not sure why. Perhaps it is actually more likely to suck up air if air is present at the pickup? Or perhaps I was a little low on oil for this test as well (but I don't think that was the case this time).

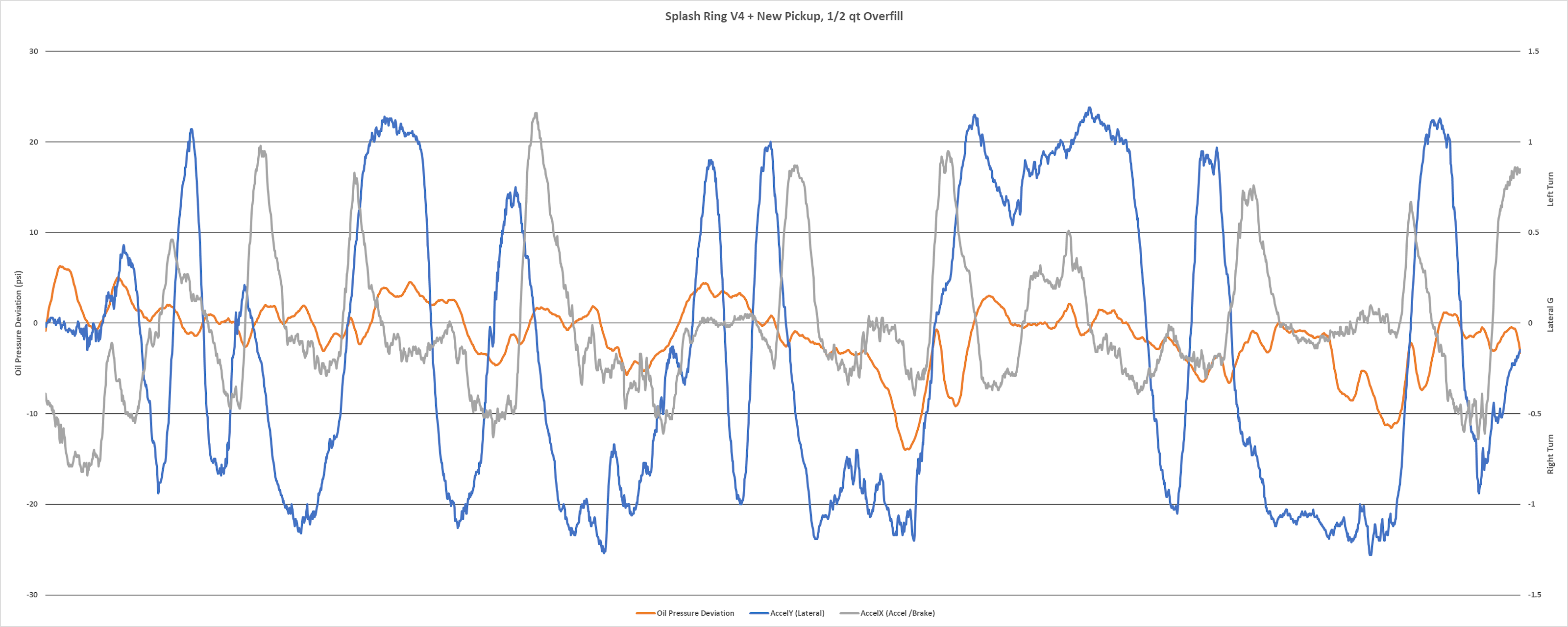

However, with an extra half quart it produces the best looking graph I have seen to date. The dips are not as deep, and on the long sustained RH corners the dip is delayed much later in the corner compared to some tests. There are some RH corners with no pressure dip at all, which is pretty huge.

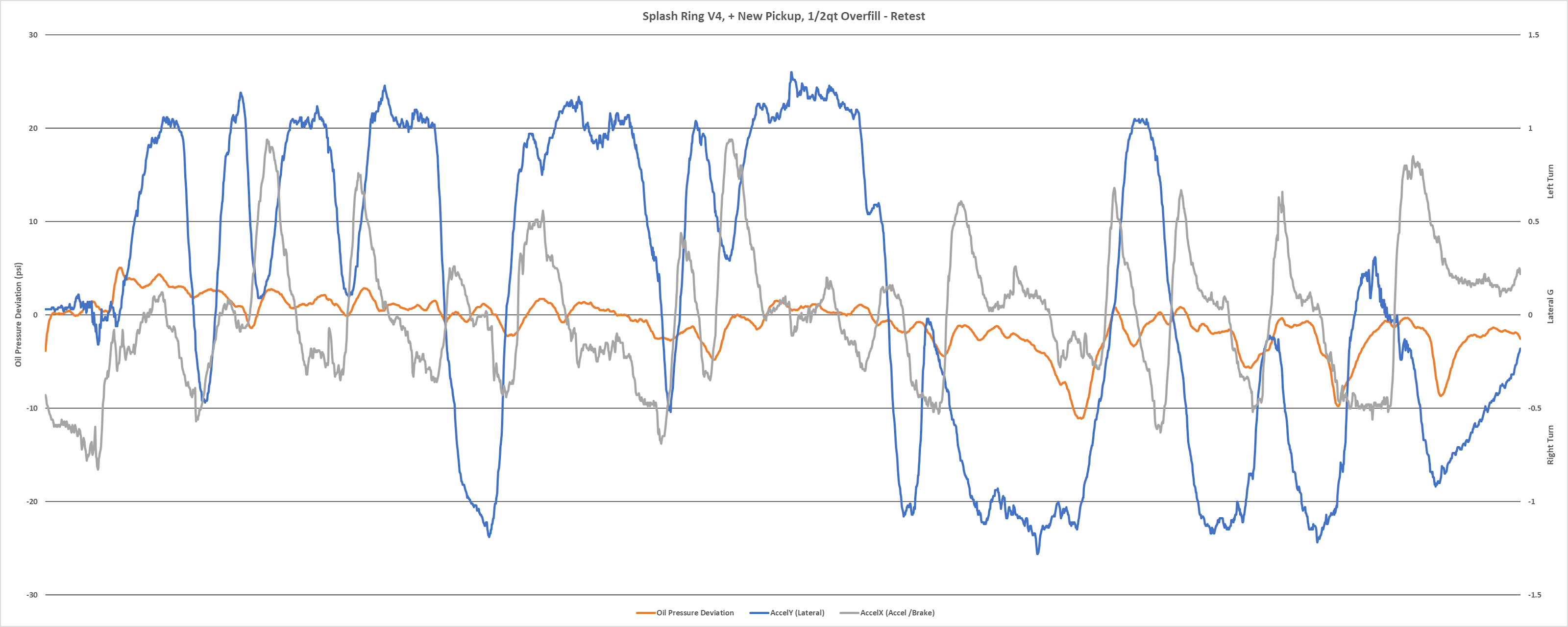

To verify these results, I ran another autocross with the exact same setup, and got very similar results on a different course.

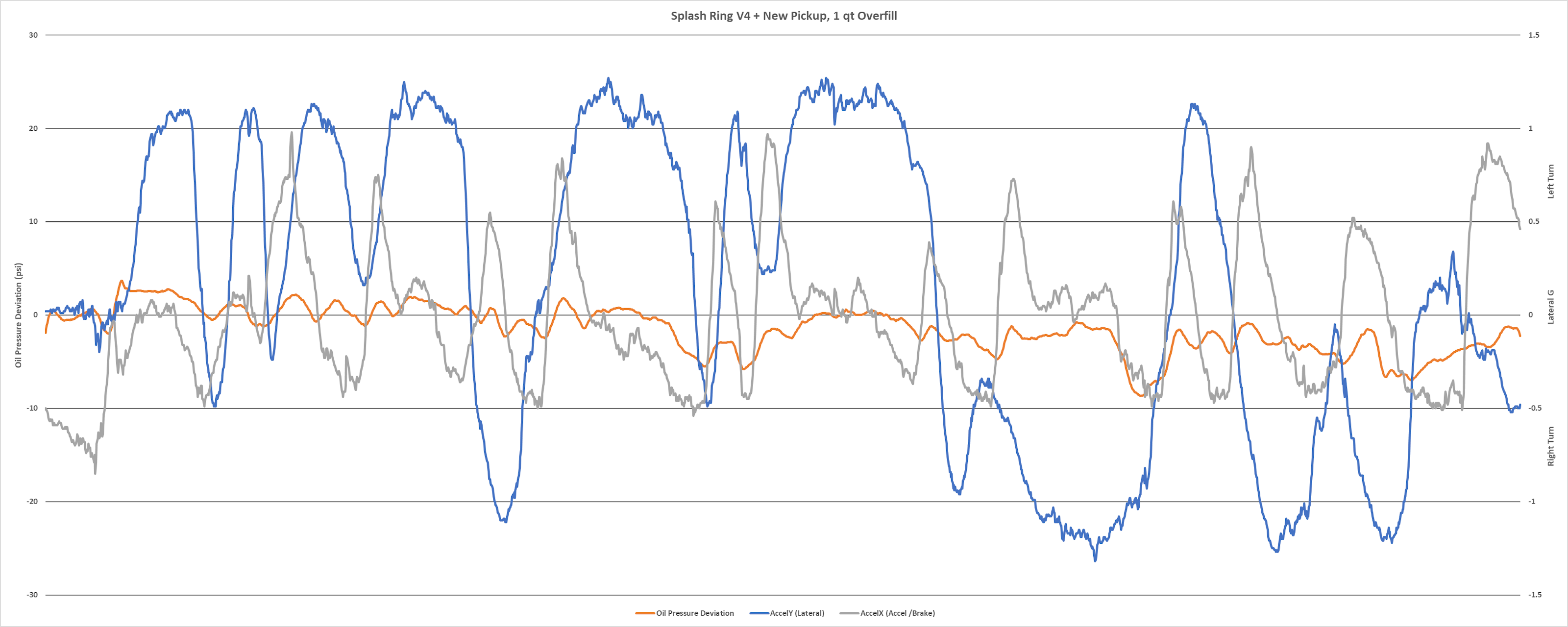

At this event I also tried retesting a full quart overfill, which showed additional improvements in the pressure data. In the past (without a catch can) I observed smoke an measurable loss in oil level over the course of a day if I started with a full quart over fill, but with my catch can there do not seem to be any downsides to overfilling to this degree. I do NOT recommend it unless you have a catch can with a drain back to the sump.

Final Thoughts

OK, that was a lot of graphs and if you made it this far, thank you! Sorry for the data overload. There is one last way of looking at all of this that is a little more quantifiable than the graphs, and that is to count the dips over an autocross run. Now, every autocross course is different and this method could easily produce misleading results. If I had a course with nothing but LH turns, the oil pressure data would look great! But if you look at the graphs you can see that my region tends to run courses with a decent mix of LH and RH turns and so counting dips seems like a decent double check on the results. I counted dips of greater than 20 psi, and also those between 10 and 20 psi separately. Note that for the first three with the 10hz data, I counted multiple close dips as one, and even then the lack of smoothing may lead to an artificially high number of dips. Also note that while Baffle V7 shows a relatively low number of dips (the same as the V1 baffle actually) the sustained length of the dip makes them much worse than this method might lead you to believe.

| Baffle Configuration | Dips -20 psi | Dips -10 psi | Total |

| No Baffle | 4 | 15 | 19 |

| No Baffle +1/2qt | 1 | 12 | 13 |

| Baffle V1 | 0 | 11 | 11 |

| Baffle V7 | 1 | 10 | 11 |

| Baffle V7 +1/2qt | 1 | 8 | 9 |

| Splash Ring V1 | 1 | 10 | 11 |

| Splash Ring V1 +1/2qt | 0 | 3 | 3 |

| Splash Ring V2 | 2 | 9 | 11 |

| Splash Ring V2 +1/2qt | 1 | 3 | 4 |

| Splash Ring V3 | 0 | 5 | 5 |

| Splash Ring V4, New Pickup | 2 | 7 | 9 |

| Splash Ring V4, New Pickup, +1/2qt | 0 | 2 | 2 |

| Splash Ring V4, New Pickup, +1/2qt | 0 | 2 | 2 |

| Splash Ring V4, New Pickup, +1qt | 0 | 0 | 0 |

Overall, I'm very happy with where I ended up with the combination of the splash ring, the new oil pickup, AND a half quart or a little more over fill. None of those items on their own are a complete fix, and the data seems to indicate that the new pickup at standard oil level is not a great idea (and I still don't know why). But the combined effect of the splash ring, the new pickup, and an extra quart of oil producing an autocross run with zero dips of more than 10psi is about as good as I think we are going to do short of a full dry sump.

The Dipstick Problem

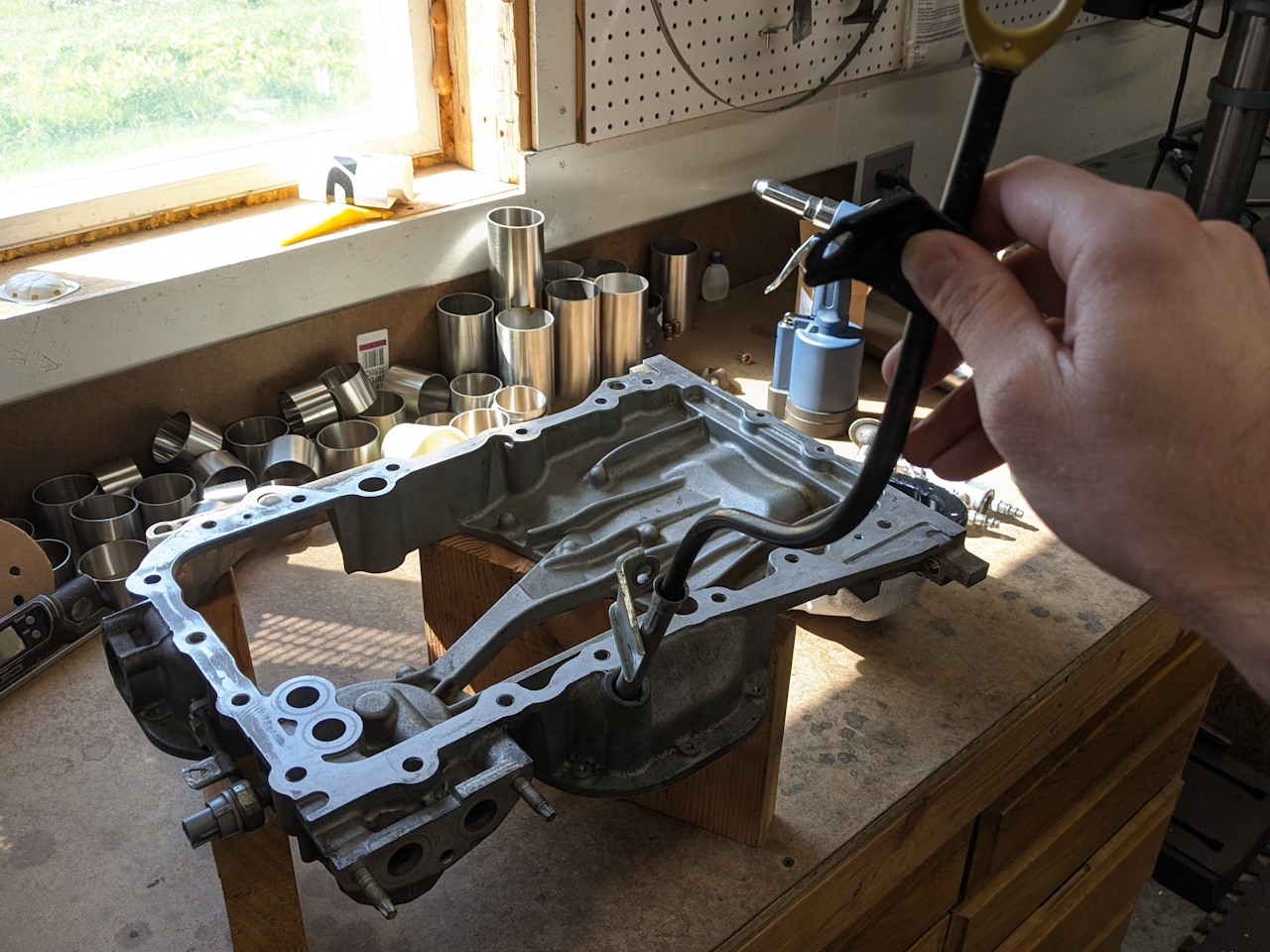

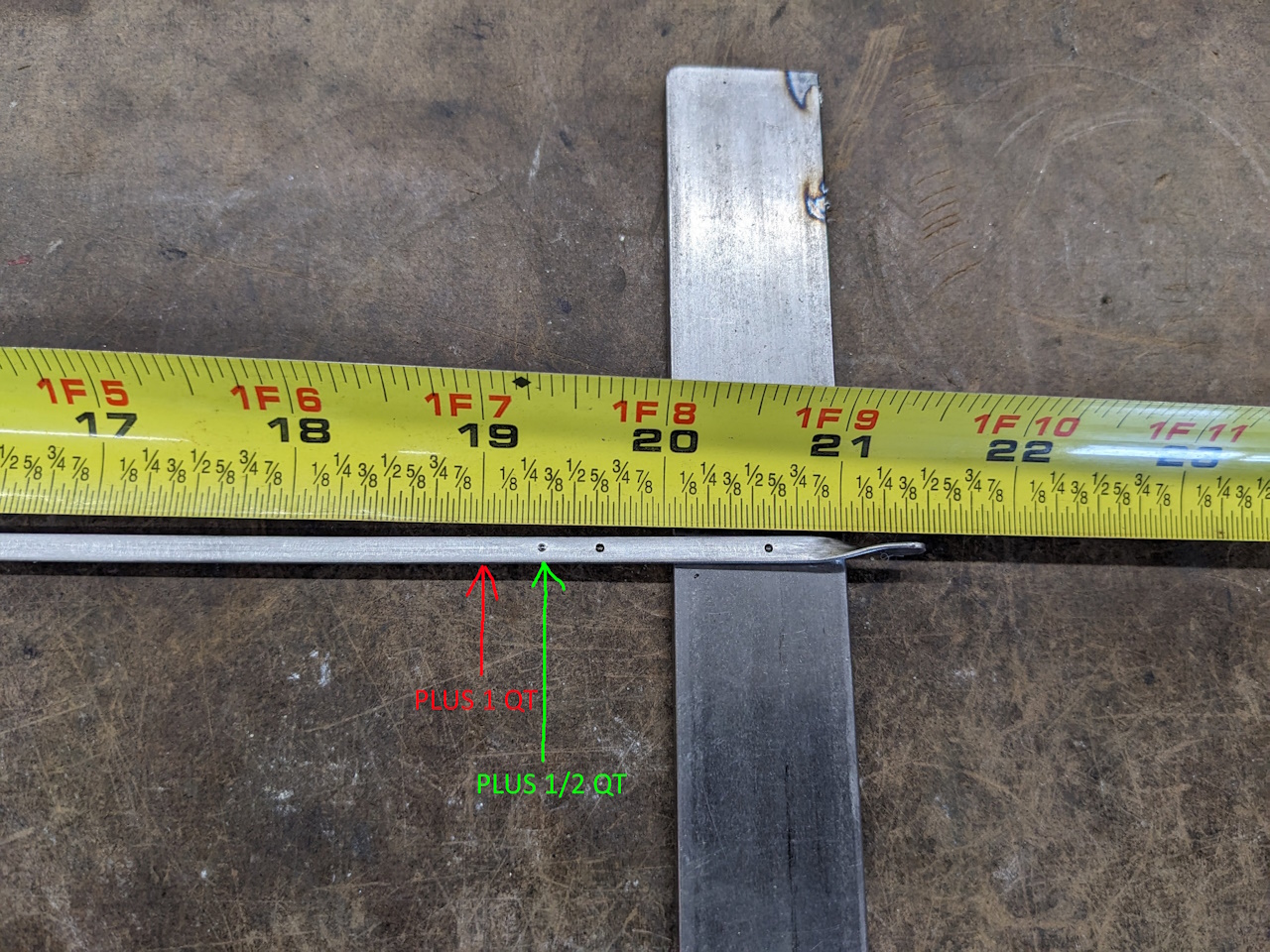

As you can see looking at the data presented here, oil level matters, A LOT! A half quart is about 0.3", or about 7.5mm, on the dip stick. This doesn't seem like much when you look at the total size and depth of the pan, yet it makes a big difference. The problem is, there are at least three different dip stick lengths that came with the 2GR in different applications. One of them is paired with a different part number for the dipstick tube (I do not know if the tube is actually a different length), while at least two others share the same tube PN. The position of the full mark on these two differs by about 0.6" / 15mm. That means that depending on which dip stick you have, your "full" level might be different from mine by about a quart. My motor came from a 2012 Rav4, which uses one of the longer dipsticks, resulting in lower oil levels at "full". The Camry and ES350 seem to be the only ones with the shorter dipstick. If you wish to replicate my results here, the best thing to do is to compare the full mark on your dip stick to the bottom of your upper oil pan while you are installing my oil pan baffle. I measured this in a bench mock up as shown below. My half quart over fill mark (green) is right at the bottom of the upper oil pan. My one quart overfill is above the bottom of the upper pan by about .3". If you check your dipstick vs the oil pan and add marks accordingly you can be sure you are replicating my over fill level.

Of course you can also just measure the dipstick directly, although this relies on the tubes being all the same length and I don't know for certain that they are. But here's how mine measures for reference.

Wilhelm Raceworks 2GR-FE Oil Pan Baffle

Wilhelm Raceworks 2GR-FE Oil Pickup

Wilhelm Raceworks Catch Can